Quality Control - Manufacturing, Work-Order

Currently, in odoo, there are no options for 'Quality Control'. So, don't worry about that. Here we build a module that will help you to manage the quality of your products. Nowadays in the majority of businesses have Manufacturing, importing, exporting products. So you can receive goods(products) via transportation. Transportation increases the likelihood of goods being damaged. That's why you need to check product quality while you receiving or delivering products. Good quality control helps companies meet consumer demand with better products. This module will help you to analyze data of product quality checks.

Features

- 1. Text: The quality controller will have to add a description(text) about product quality control.

- 2. Measurement: The quality controller will have to add the measurements as product quality.

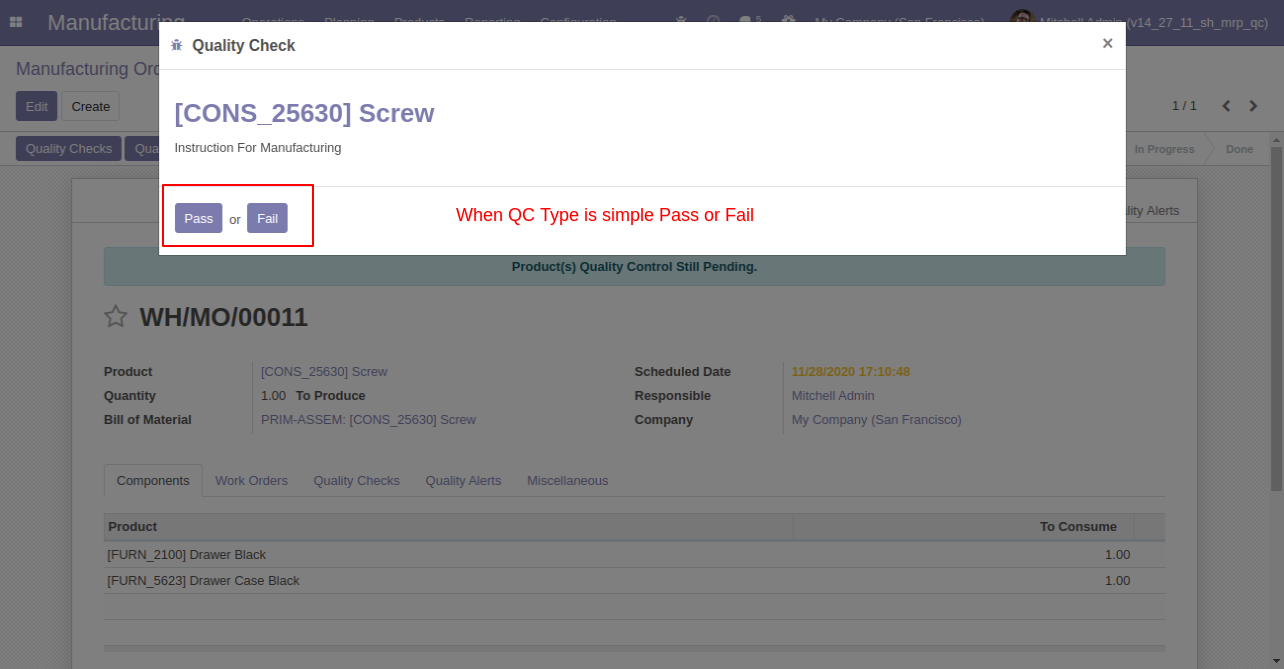

- 3. Pass and Fail: The quality controller will have to just select the product quality that is passed or failed.

- 4. Take a Picture: The quality controller will have to add the pictures which represent the quality of the product.

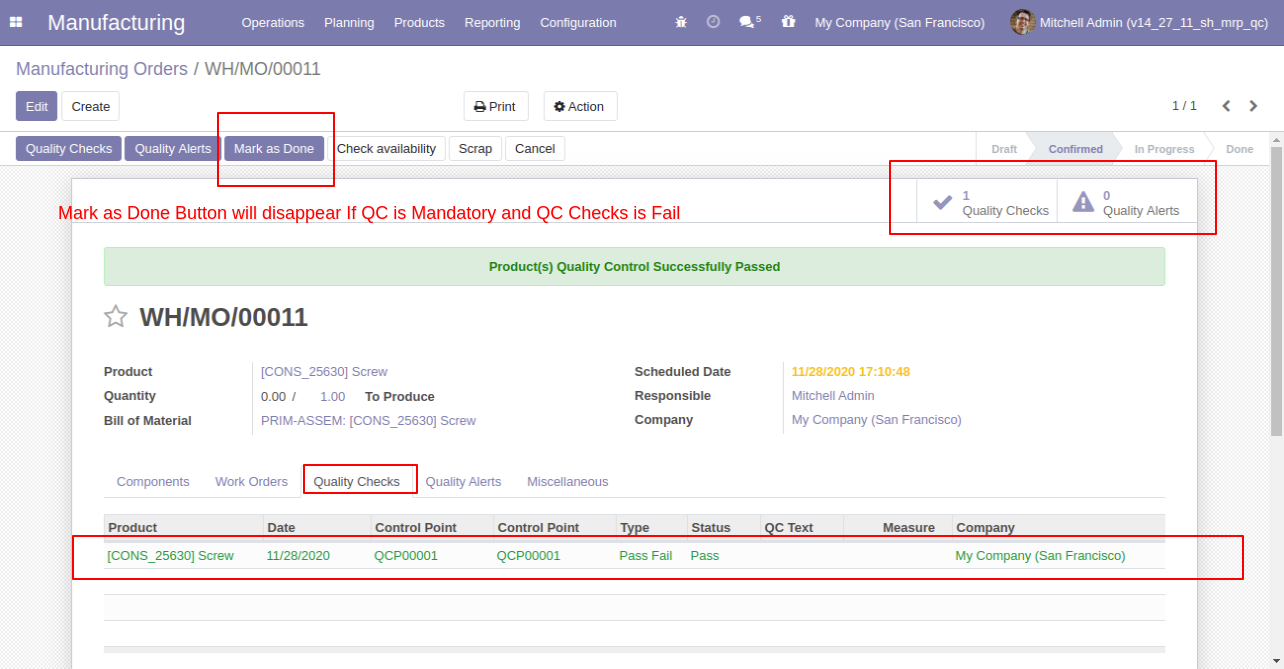

- 1. Product Quality Control Passed.

- 2. Product Quality Control Failed.

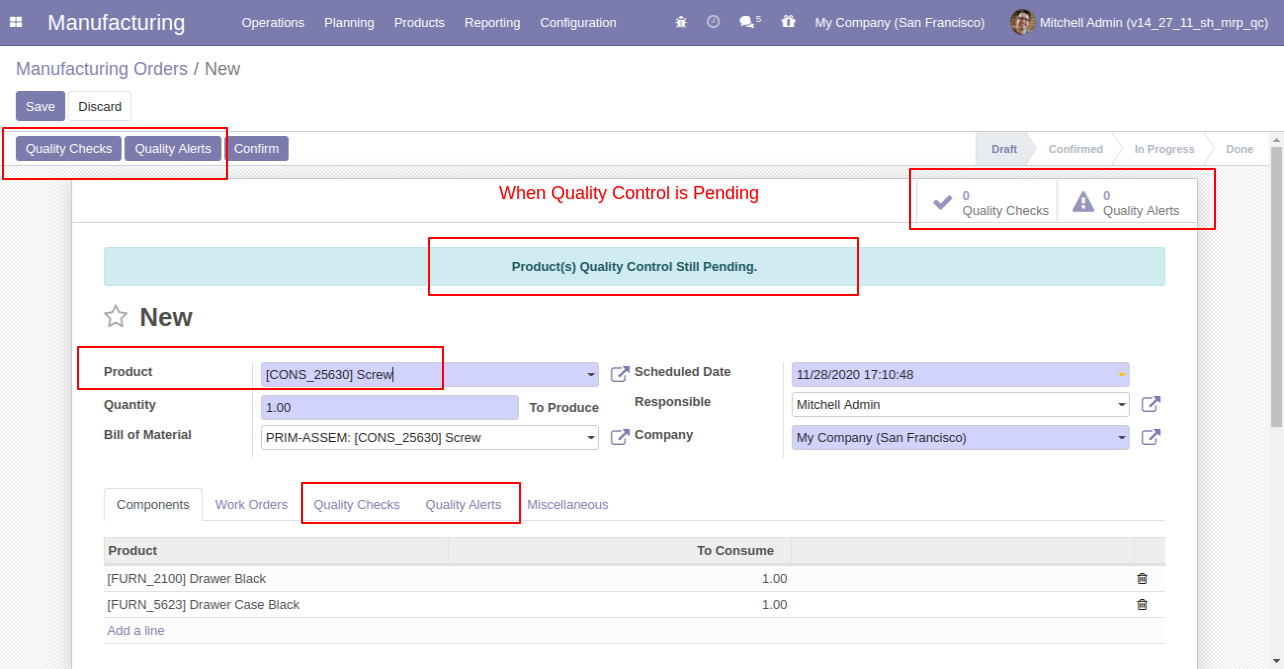

- 3. Product Quality Control Still Pending.

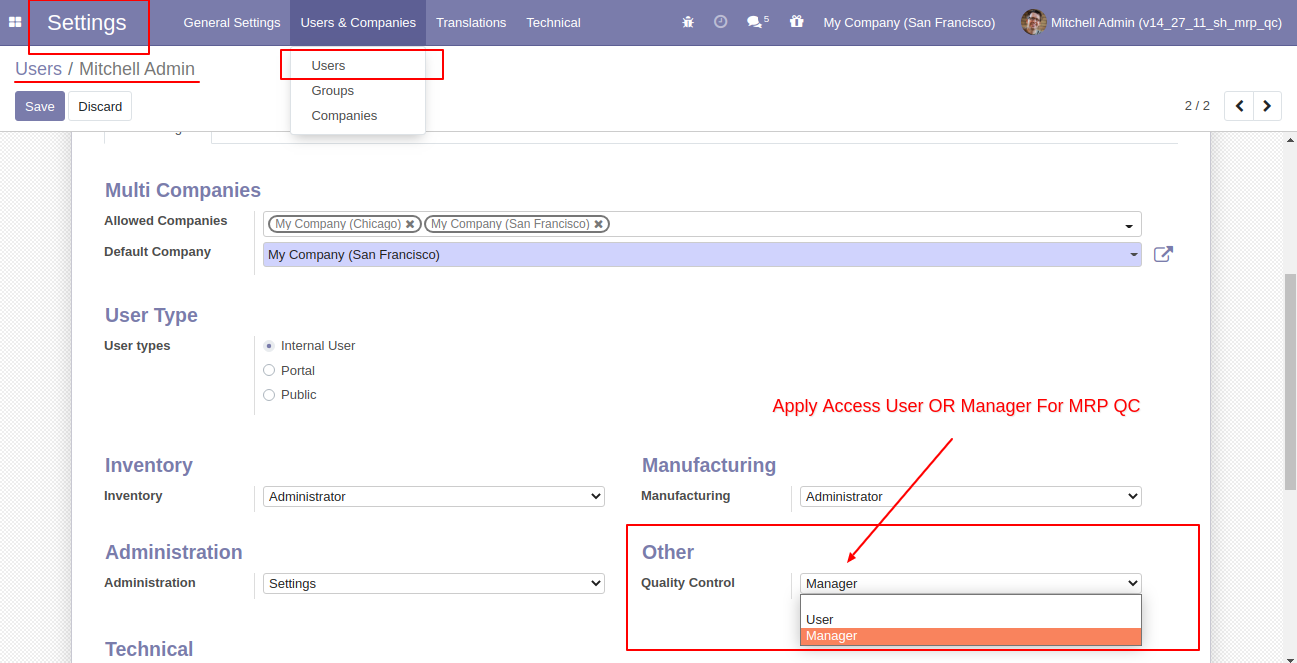

User Config Setting: There are two different user config settings for

1. Manager 2. User.

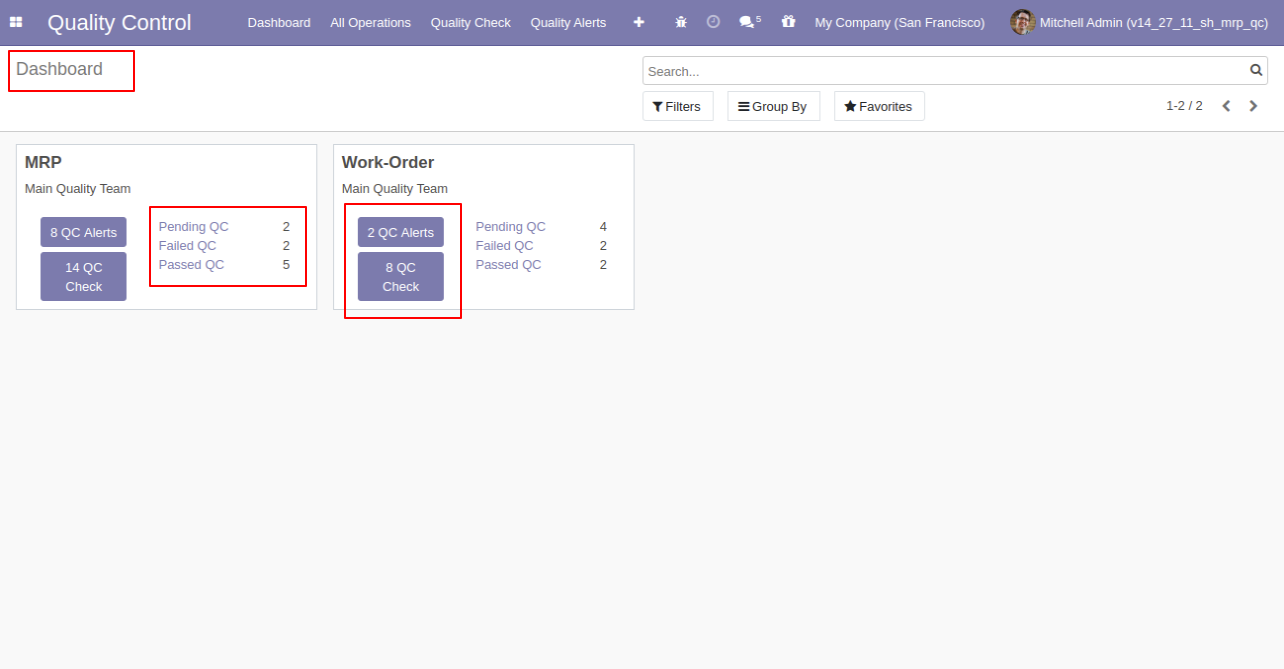

Quality Control Dashboard.

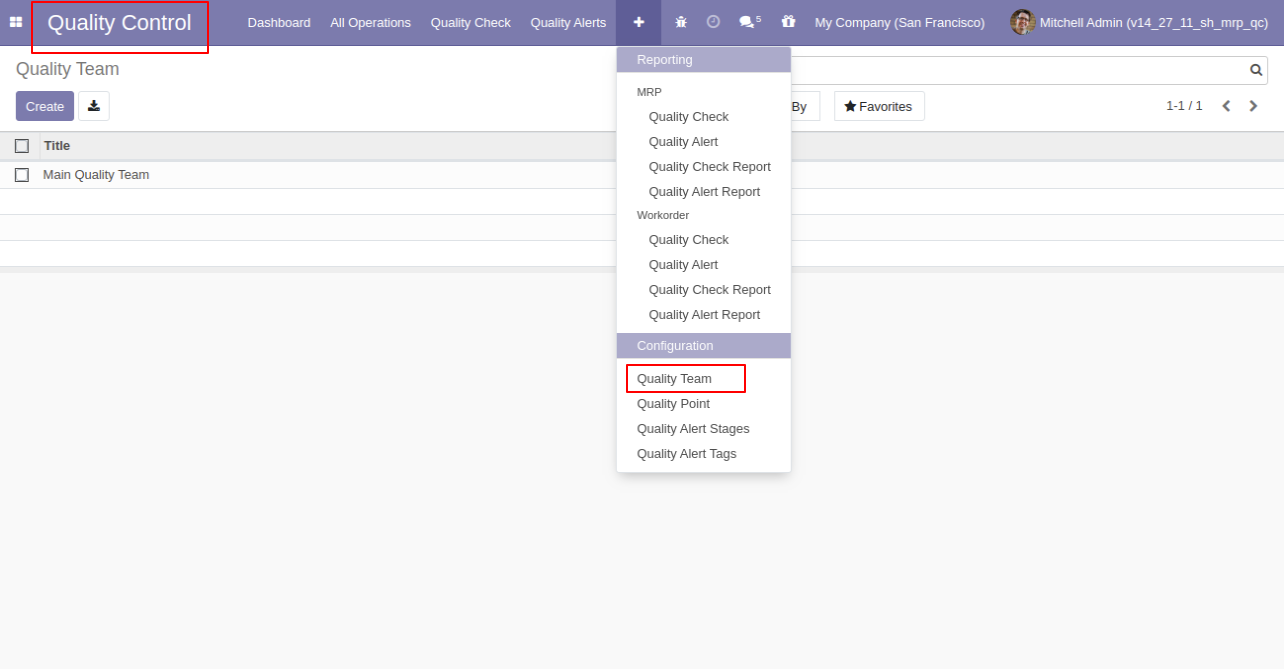

"Quality Team" Menu and Tree View.

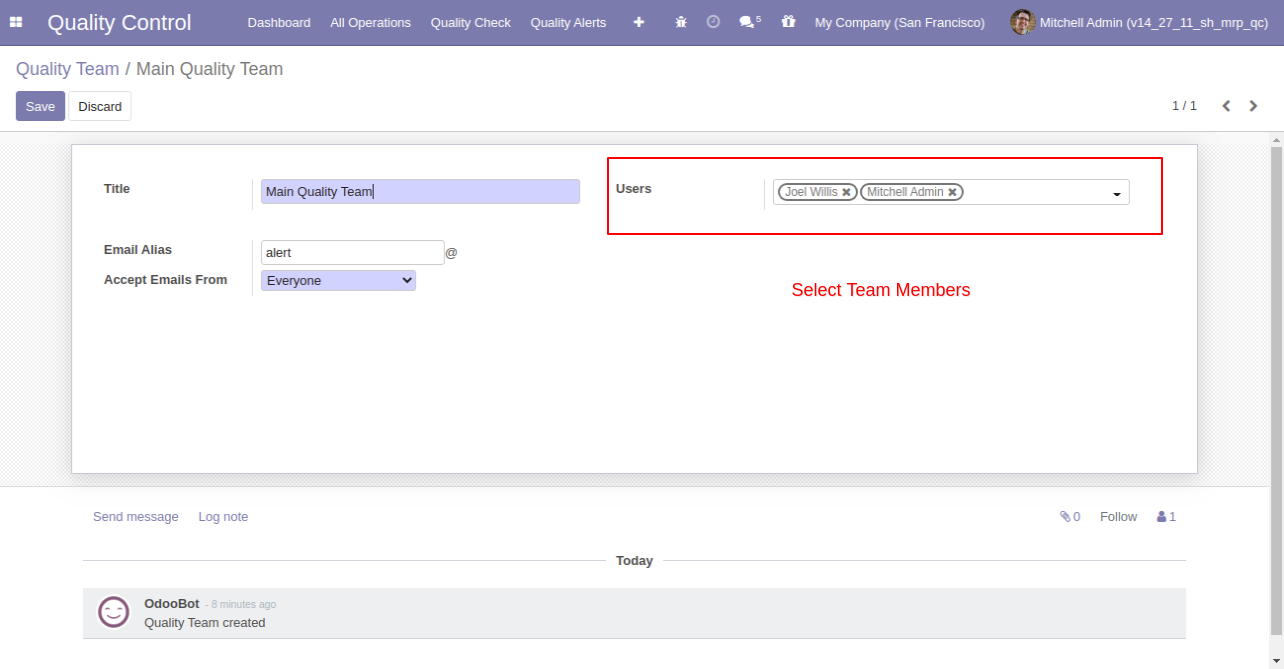

"Quality Team" Form View. Where you can define team members.

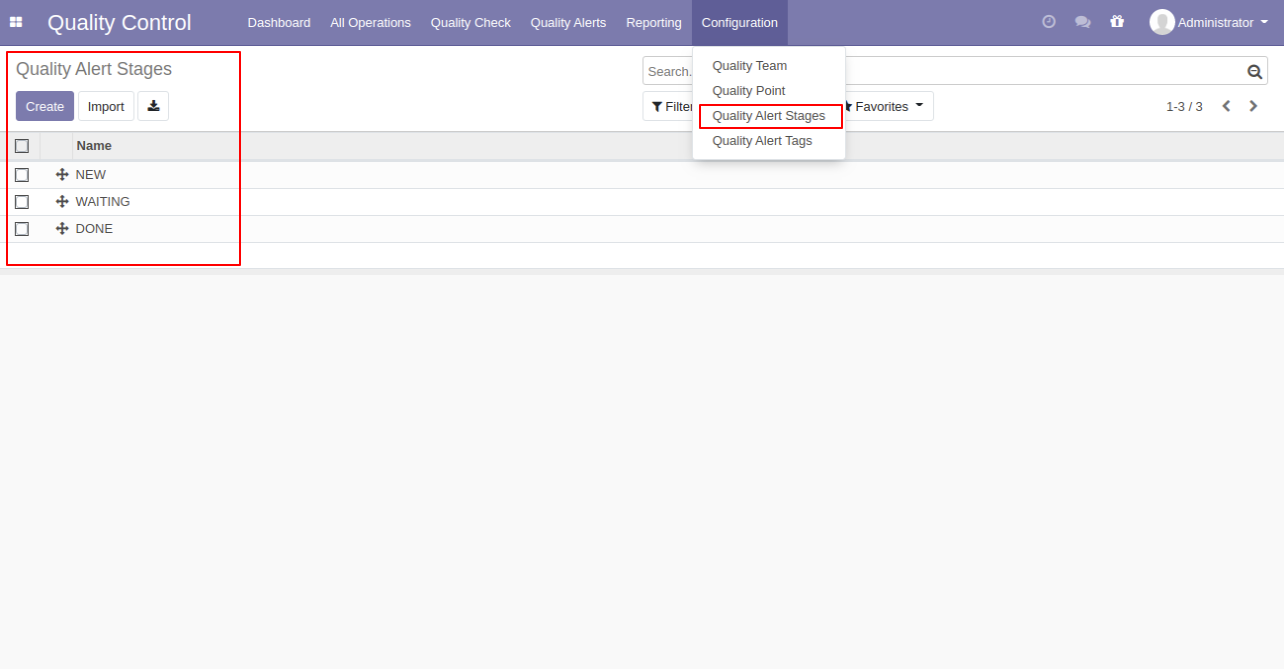

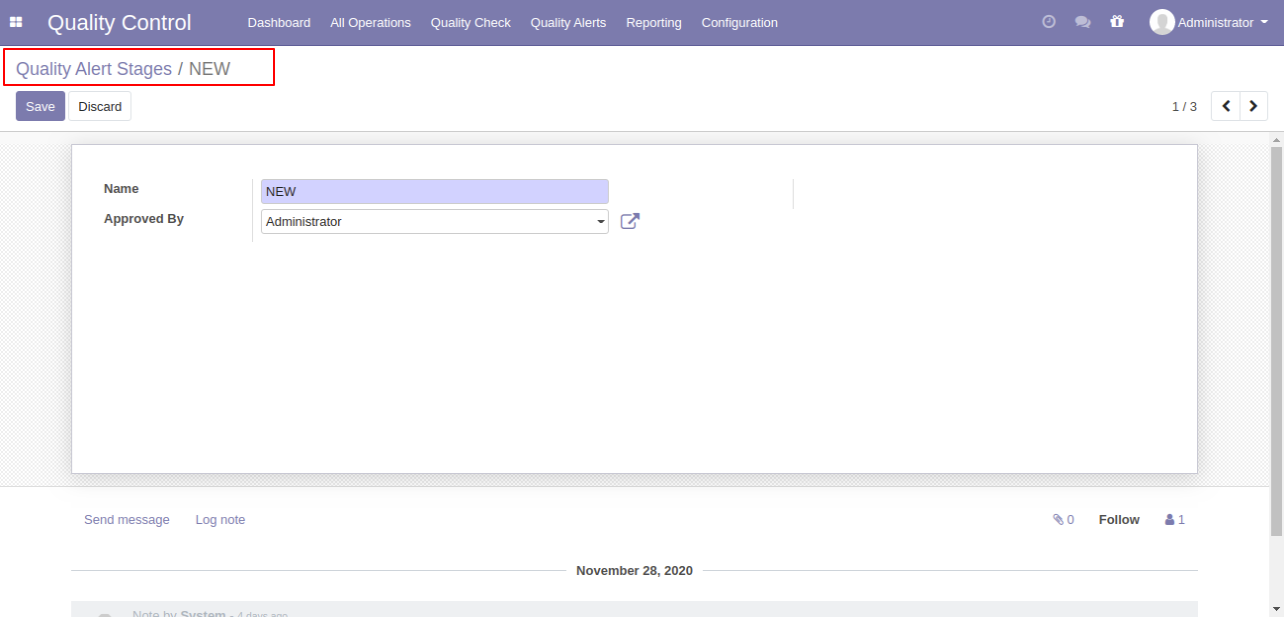

Quality Alert Stages Menu and Tree View.

Quality Alert Stages Form View. Here you can define different stages of quality control with the responsible person and company also.

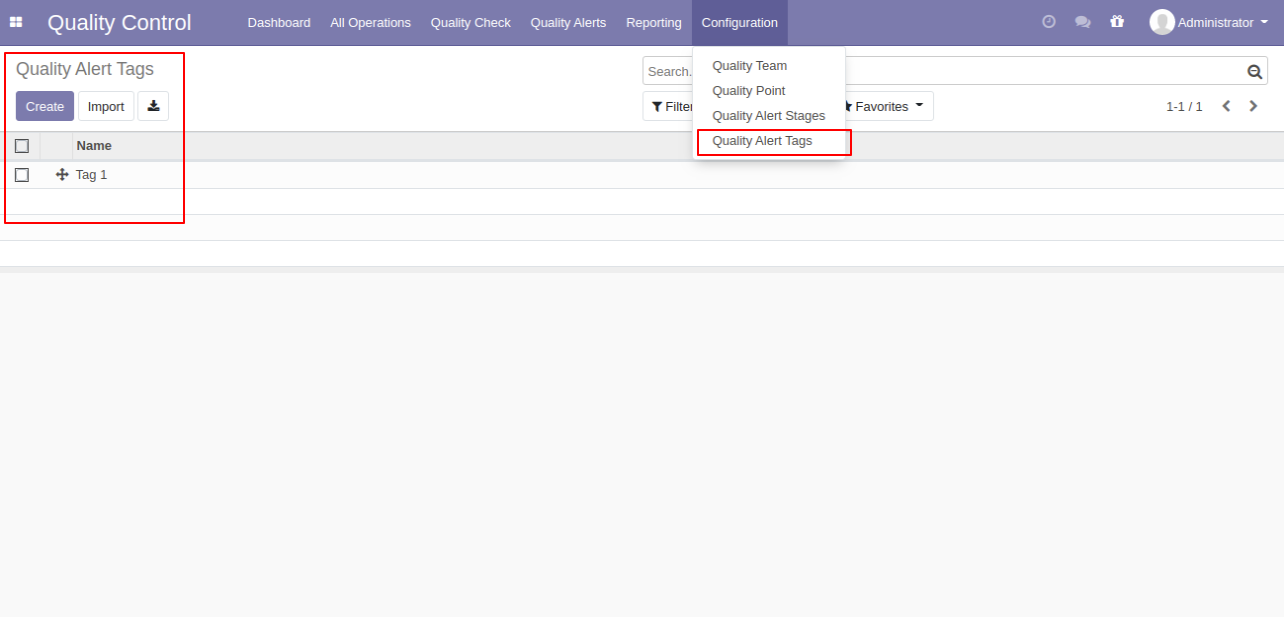

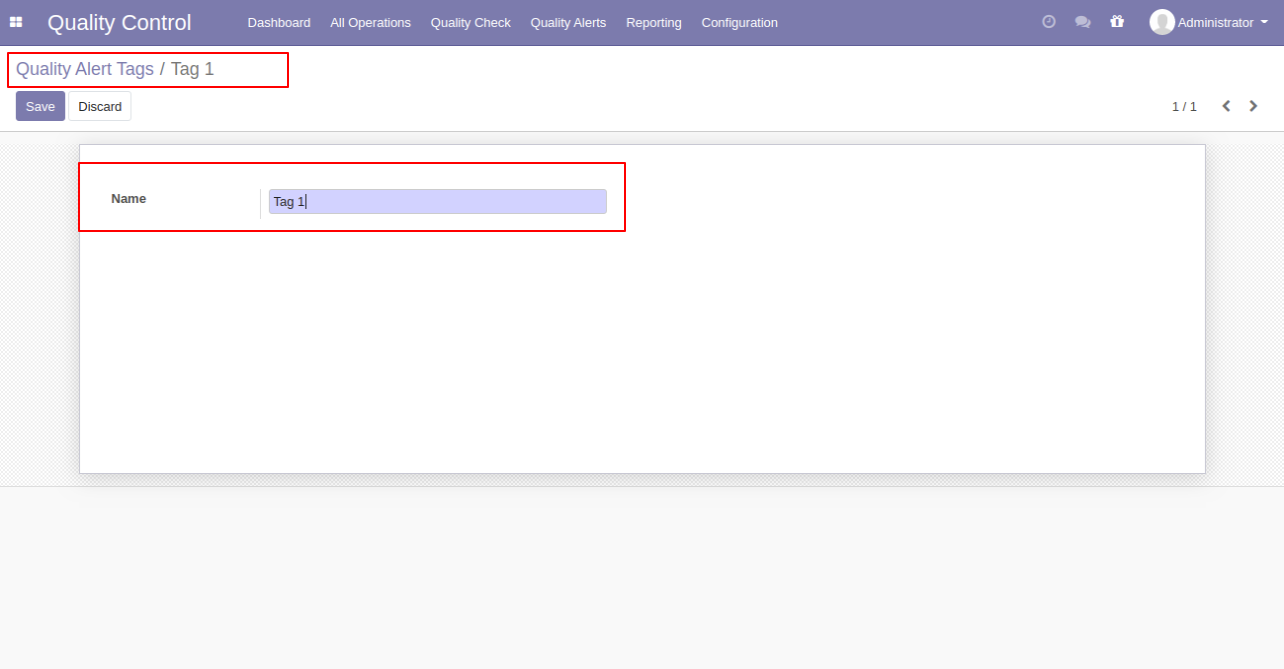

Quality Alert Tags Menu and Tree View.

Quality Alert Tags Form View.

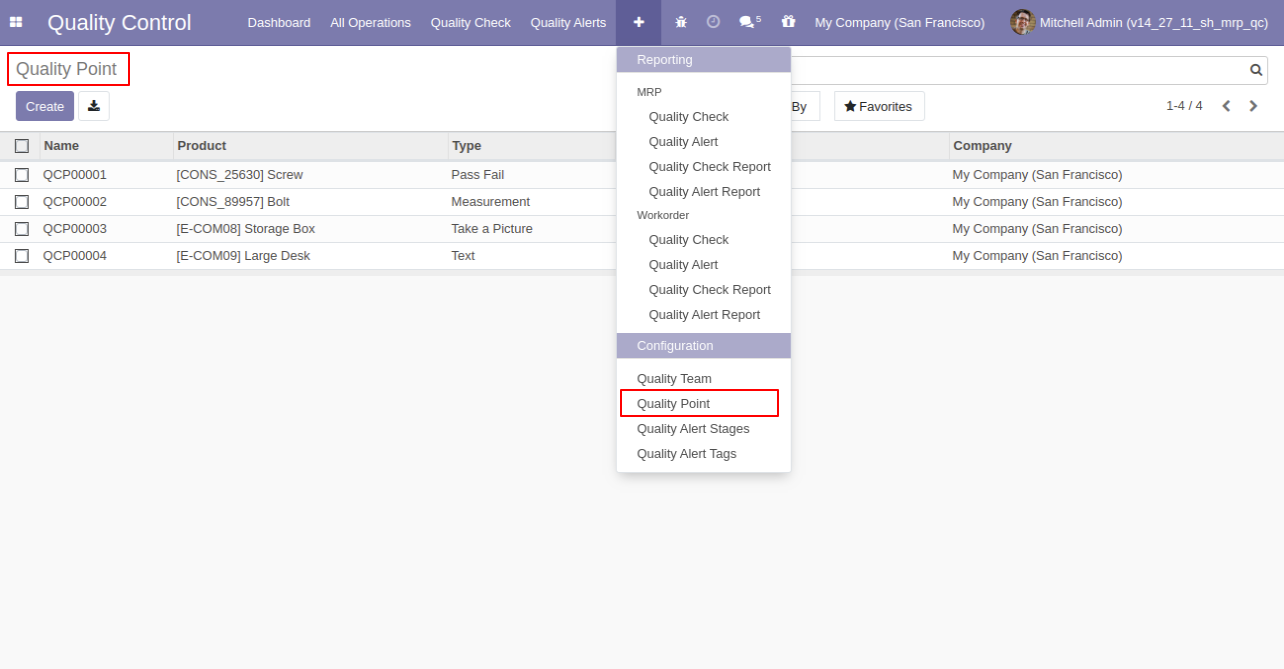

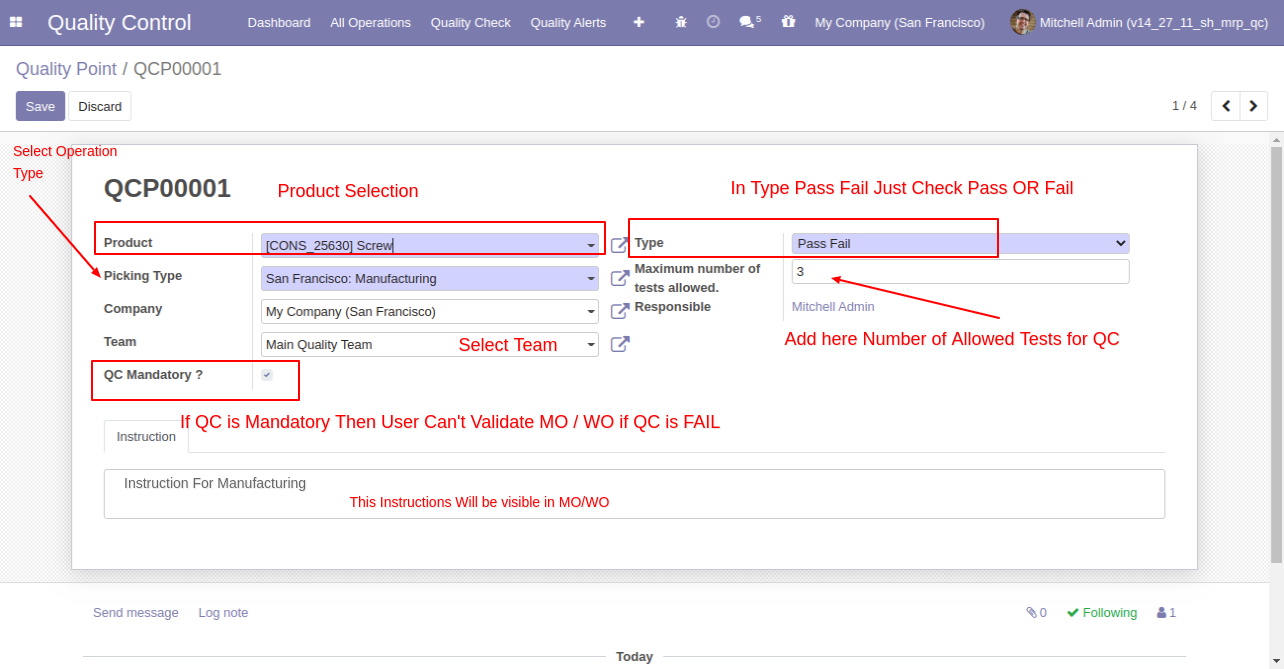

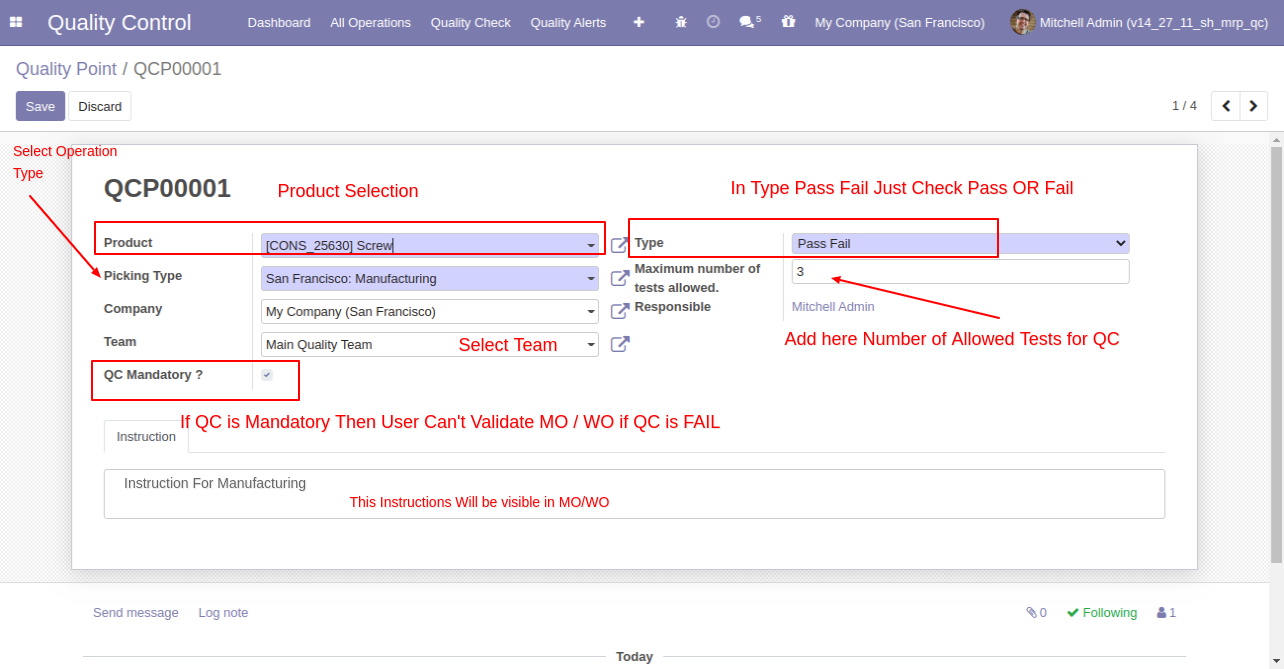

"Quality Points" Menu and Tree View.

"Quality Points" Form View. Where you can define the quality points of each product with severals points.

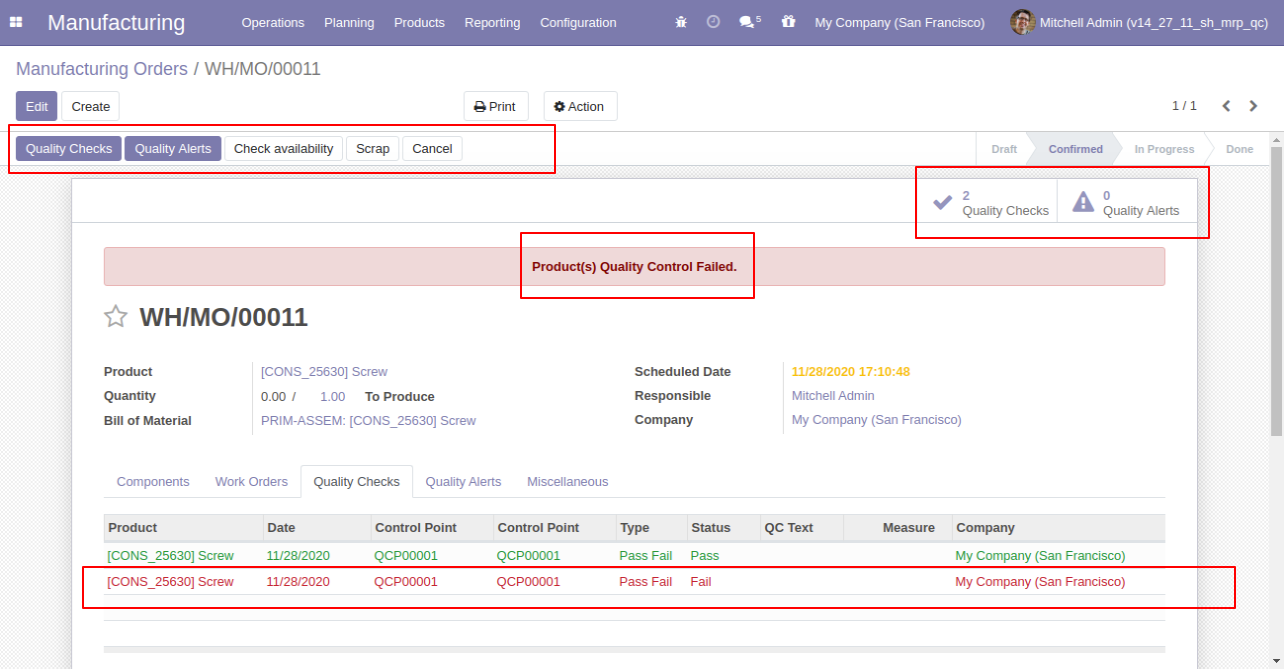

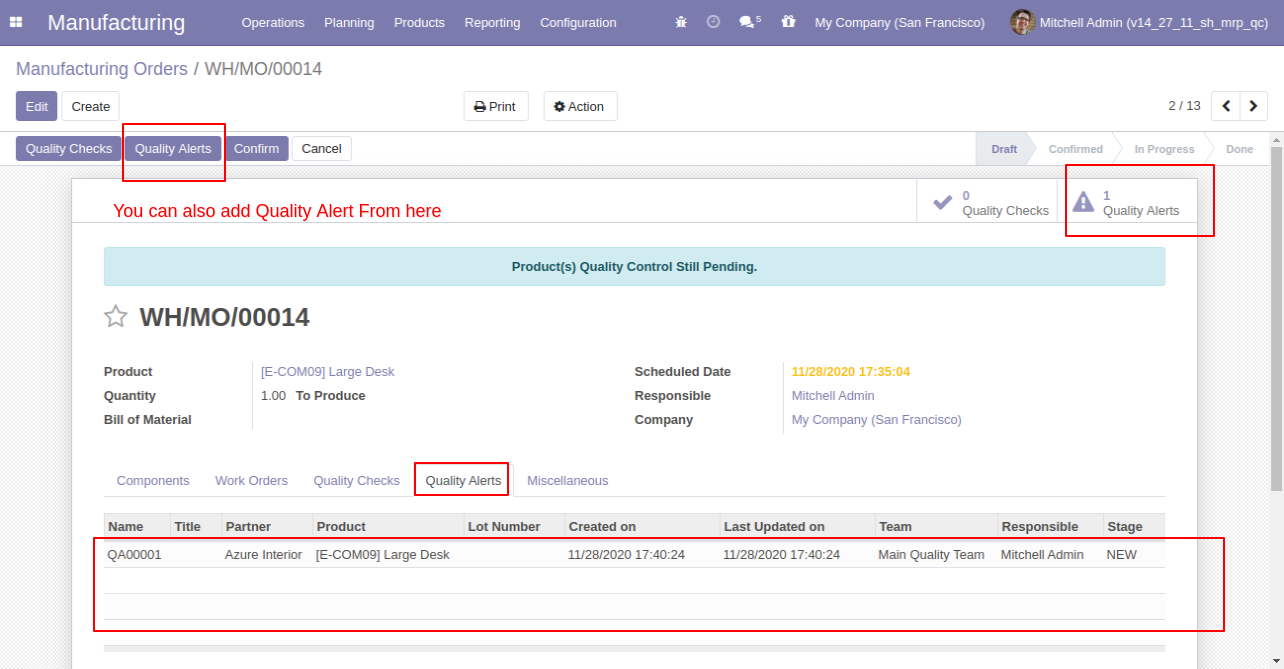

In manufacturing order form view, there are two buttons "Quality Alerts" and "Quality Check", there are two smart buttons as you can see the quality alert and quality check, also see global alert warning label on form top.

In quality points, here you can select the type of quality controls like 1. Pass or Fail.

If Quality Check is passed so it display success warning.

If Quality Check fail so it will display failed warnign and hide (*If QC is mandatory) 'Mark as Done' button

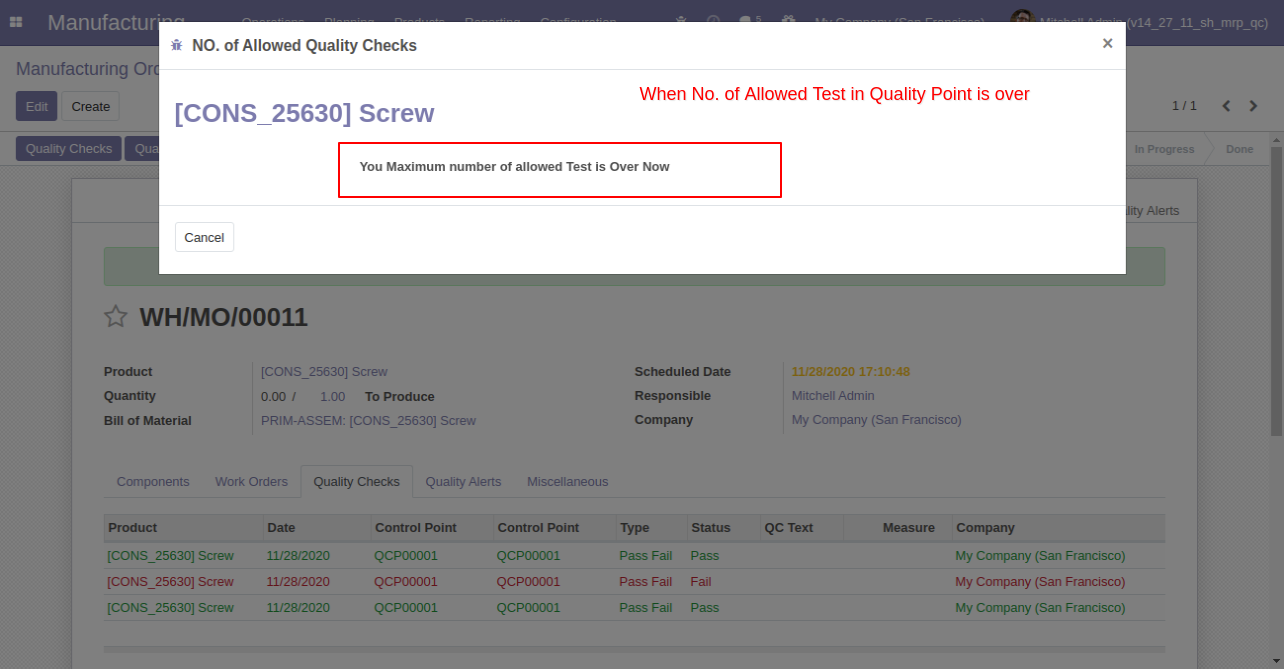

When your maximum number of quality check is exceeded that time this warning popup will display.

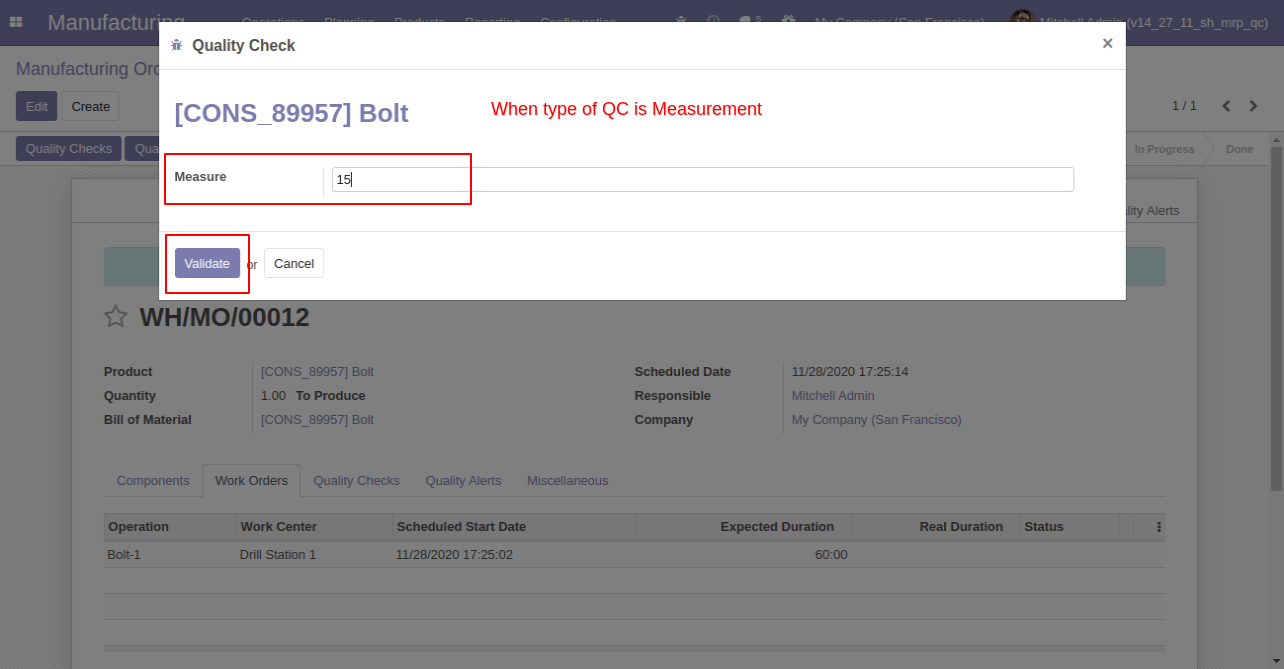

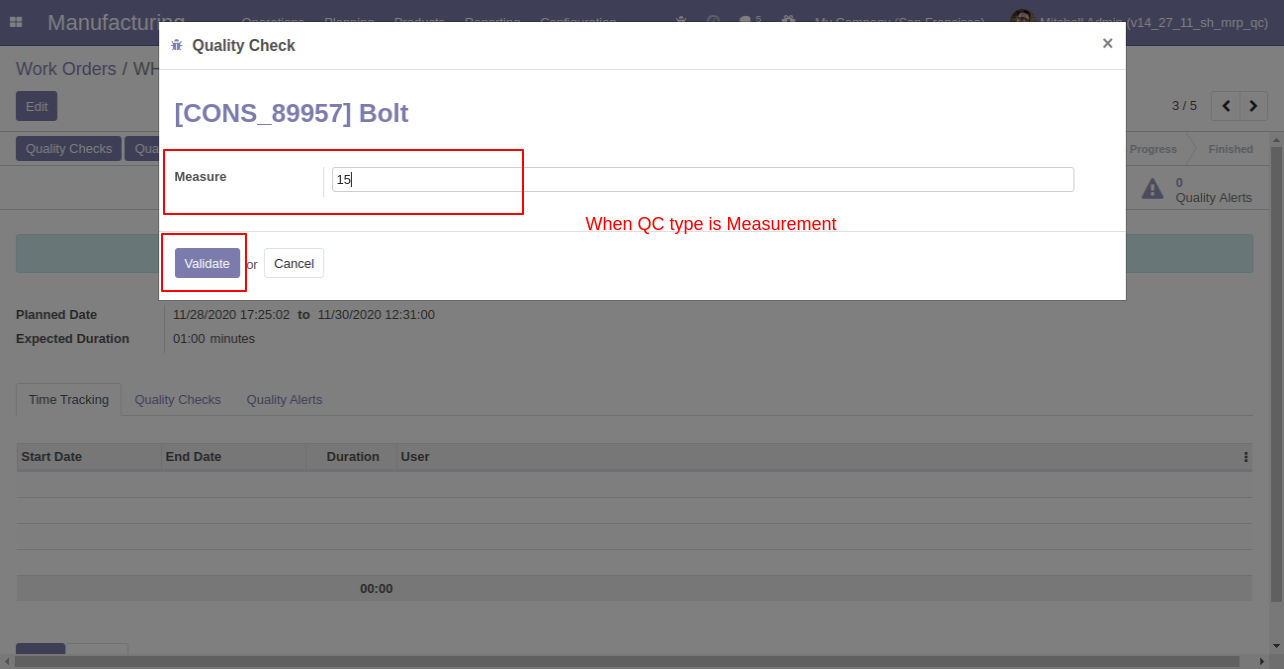

Quality Control Type 2. Measurements. In this type, you can define the tolerance level of products.

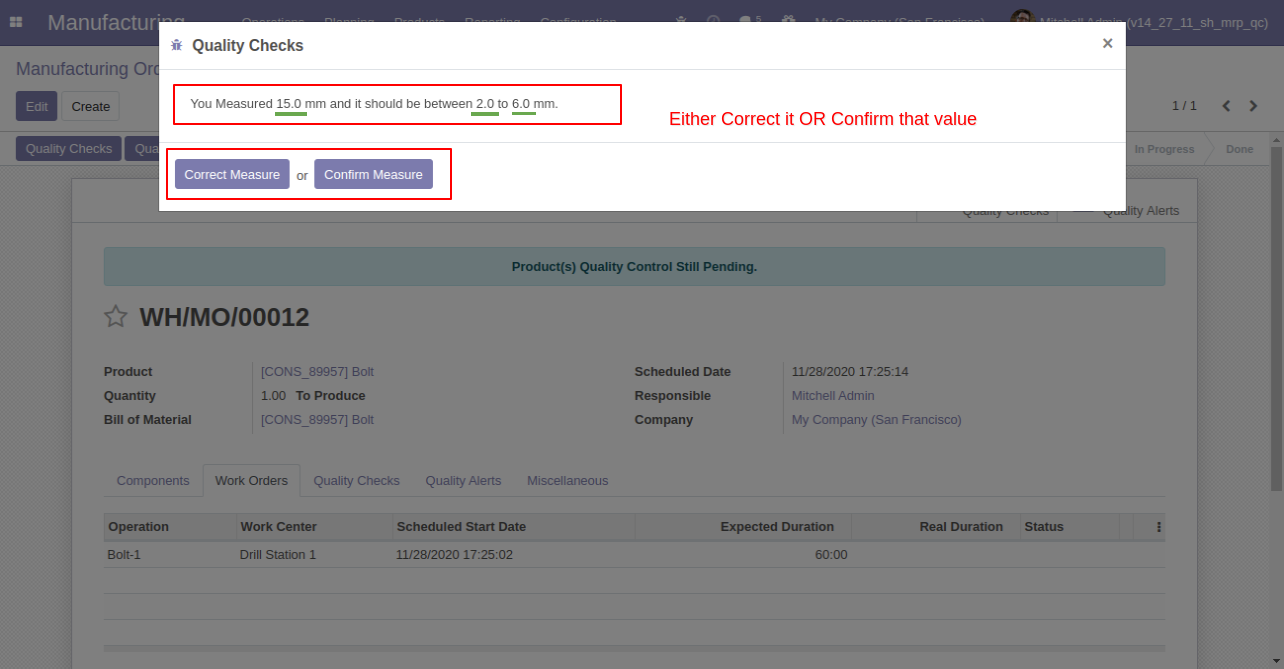

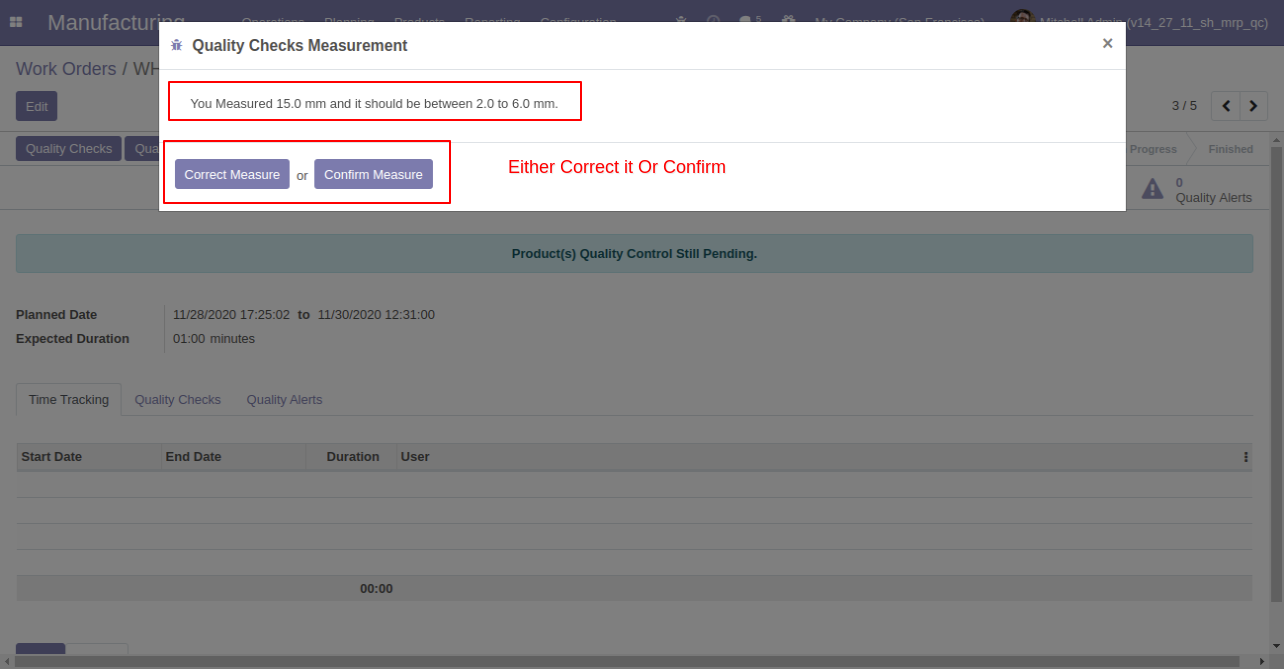

If enter measurement does not match criteria then it will popup this message where you have to select, If enter measurement is correct then click 'Confirm Measure' else click 'Correct Measure' and it will redirect to you on the previous popup.

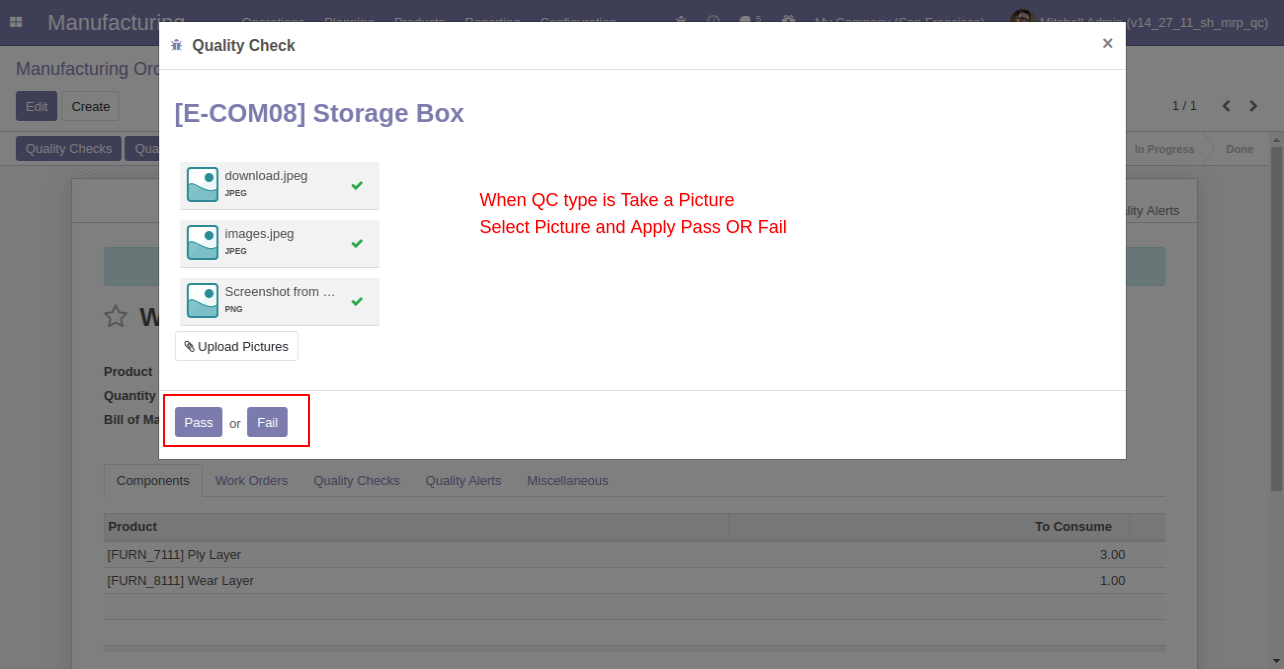

Quality Control Type 3. Take a Picture. This means a responsible person has to upload pictures of products while doing a quality check.

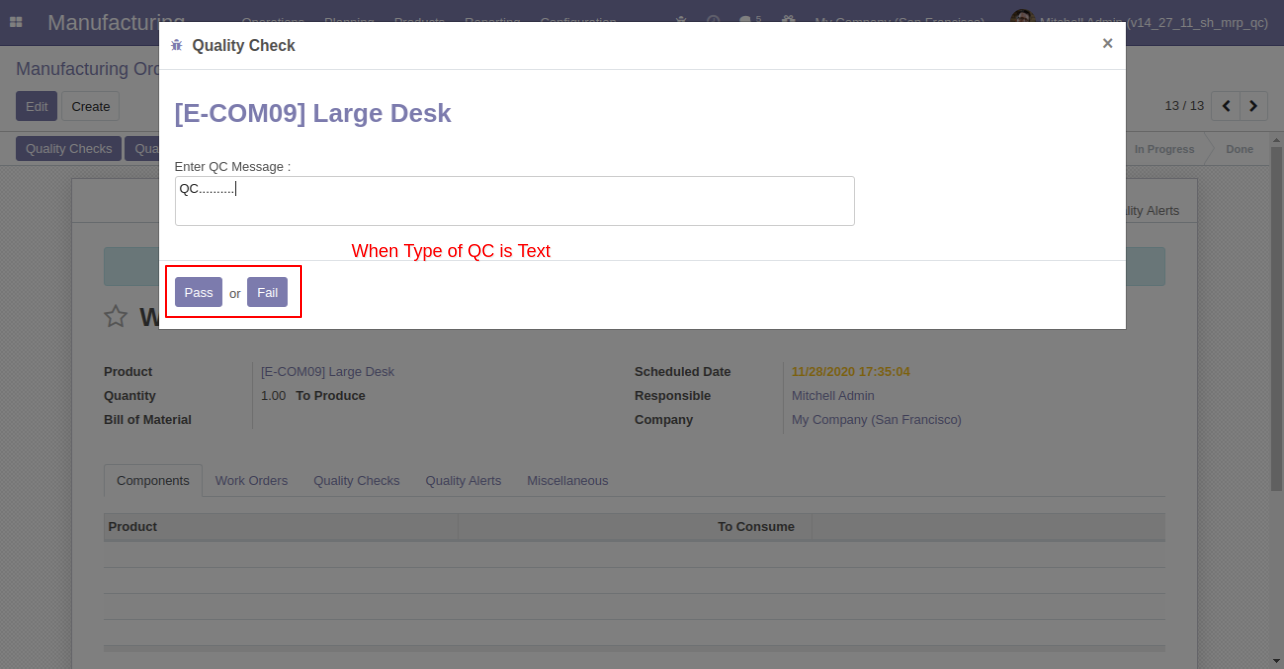

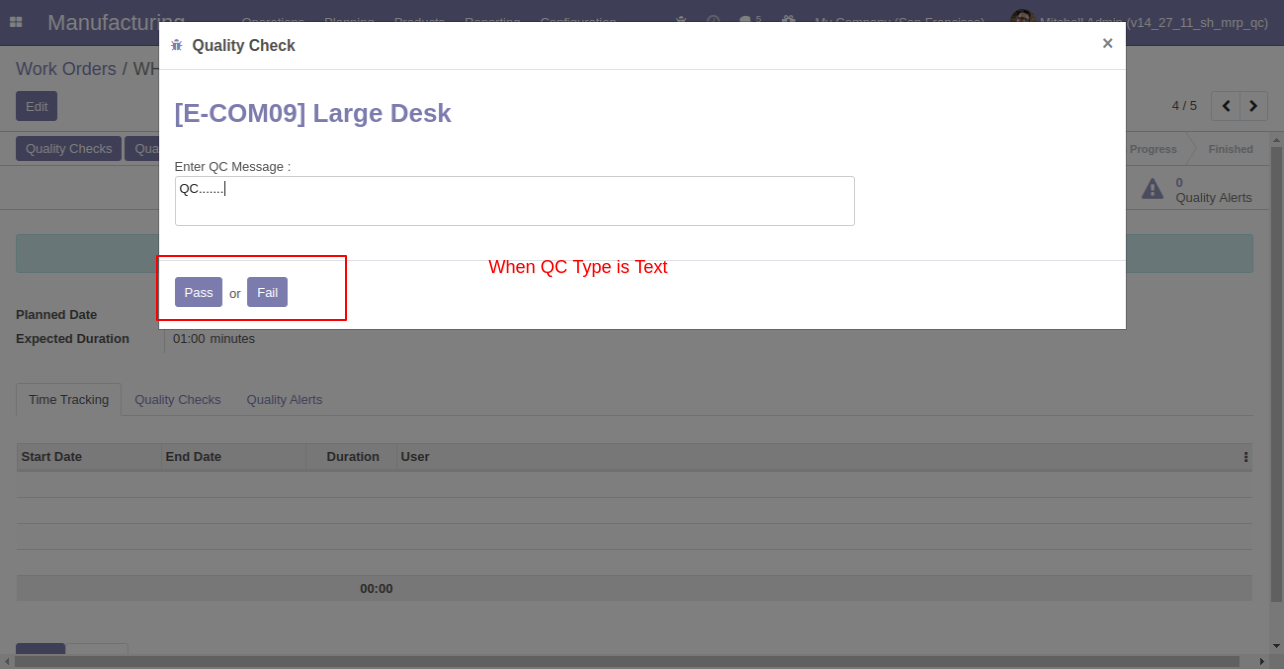

Quality Control Type 4. Text. This means a responsible person has to describe the quality of the product in only text.

Here users have buttons for 'Quality Alert' and one tab also.

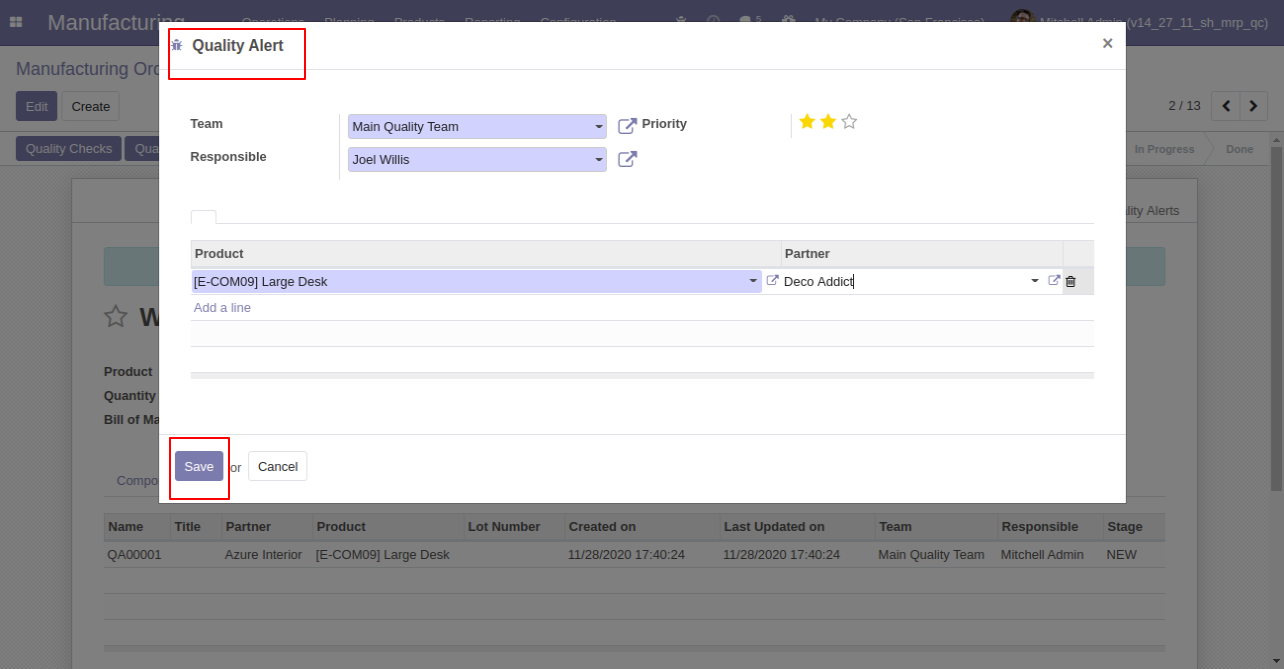

This is the 'Quality Alert' popup. Where you can see a list of all products and names of the responsible person, and priority.

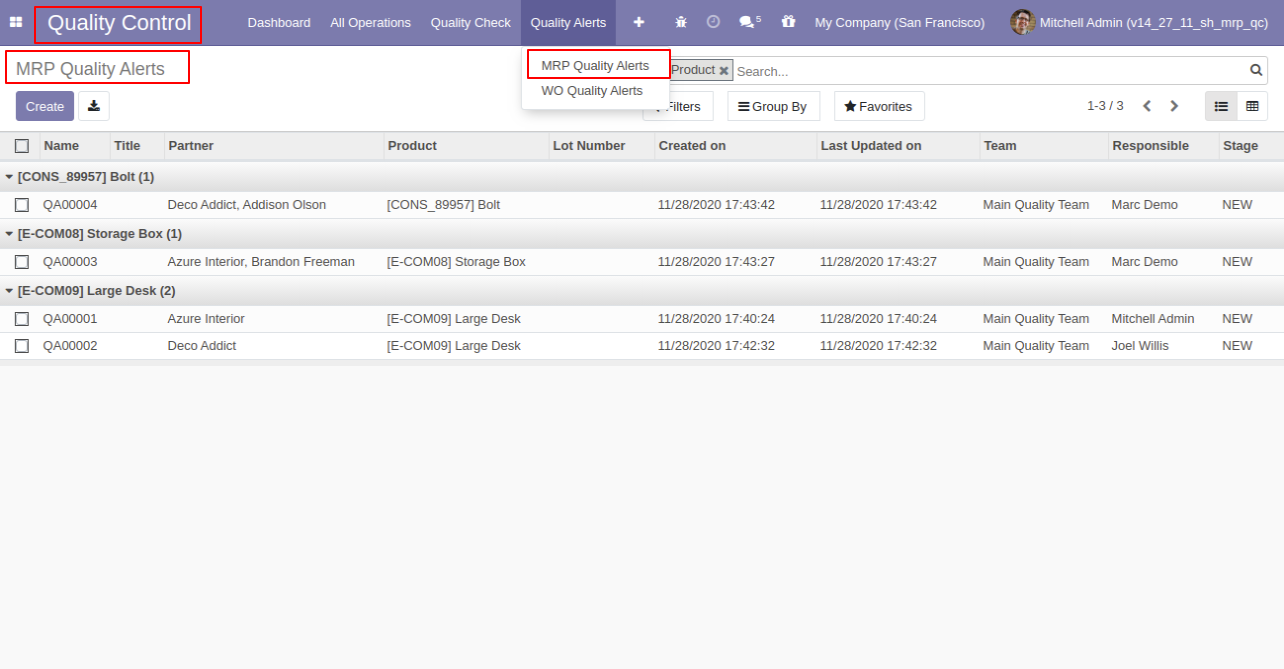

MRP Quality Alert Menu and Tree View. Where you can see the list of MRP's quality alerted.

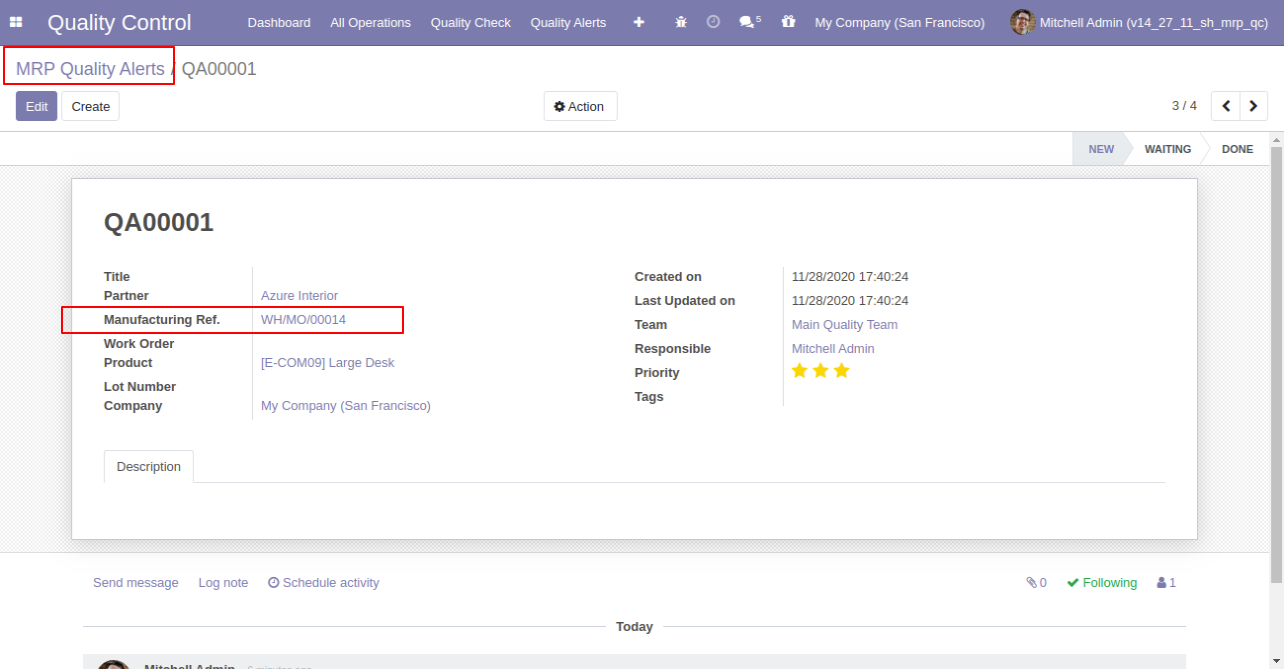

MRP Qulaity Alert Form View.

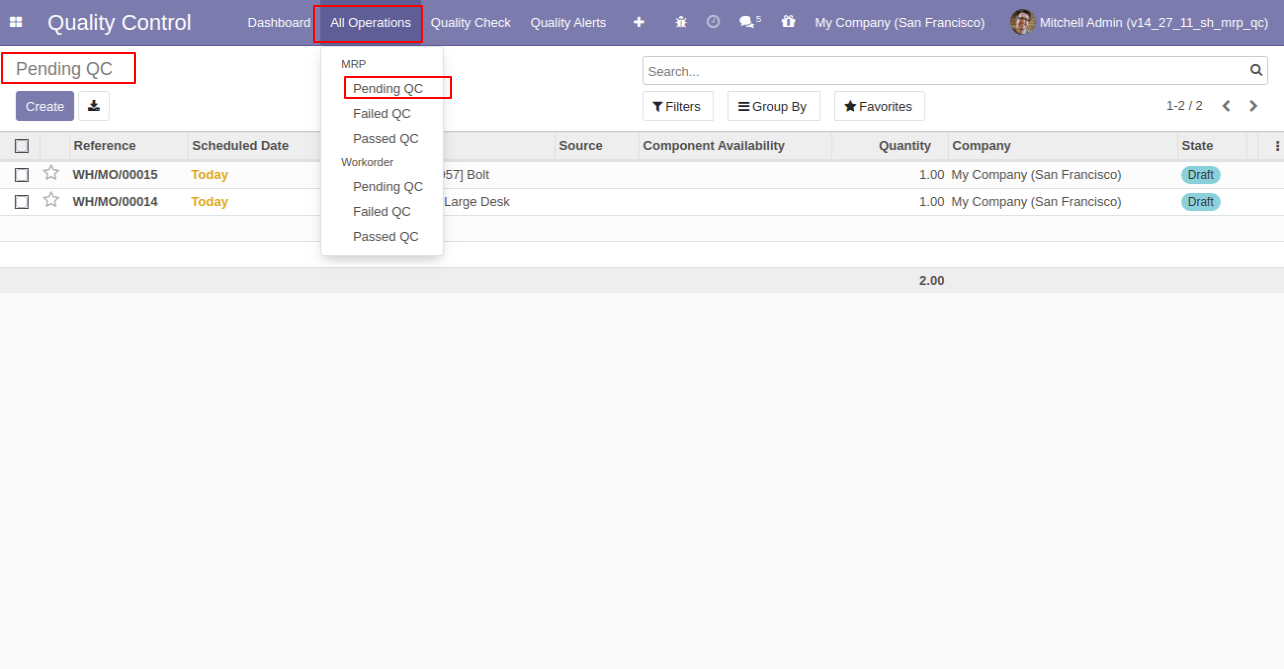

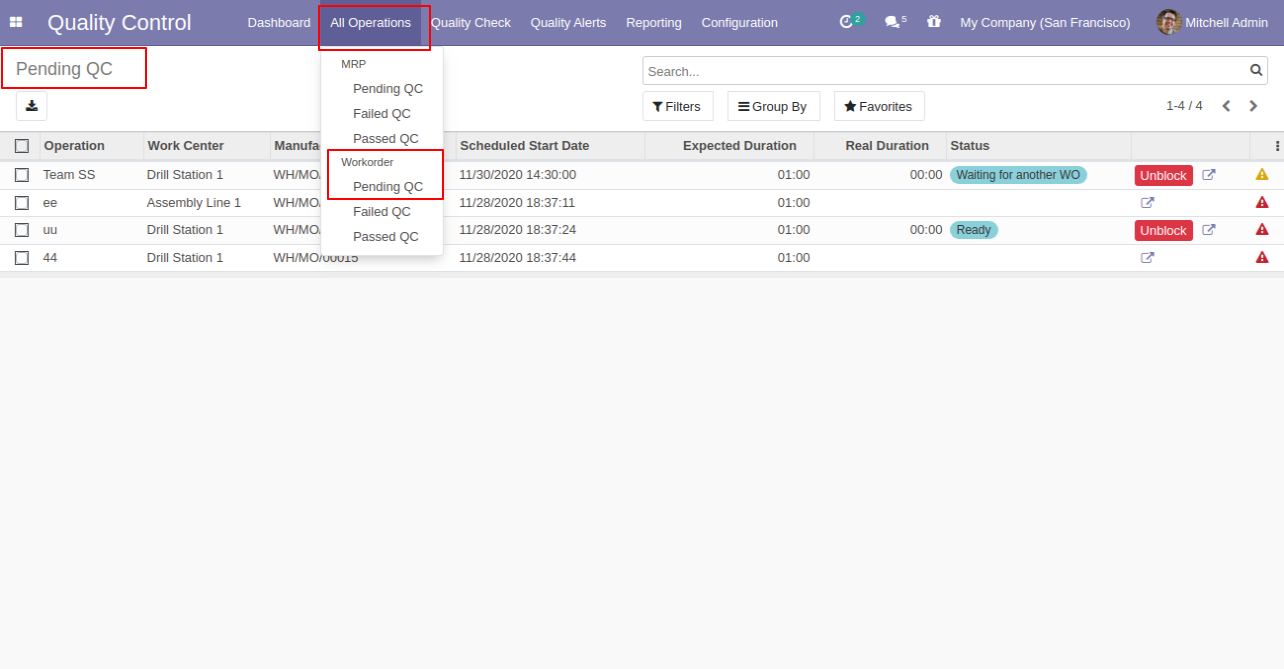

MRP Pending QC Menu and Tree View.

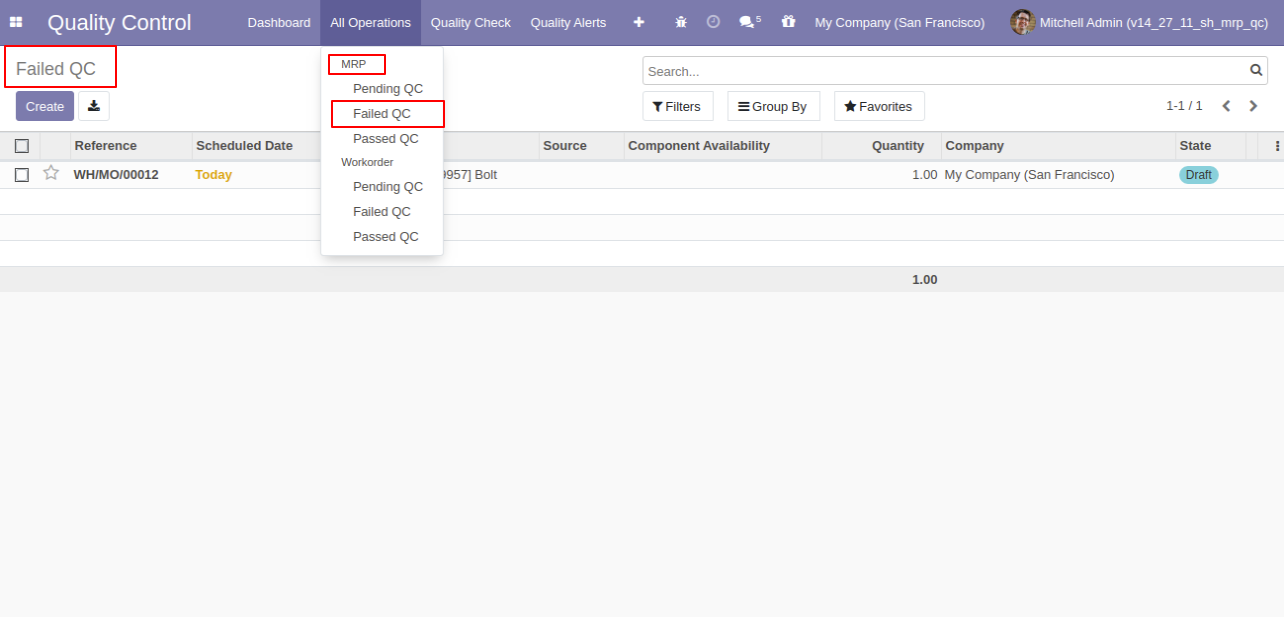

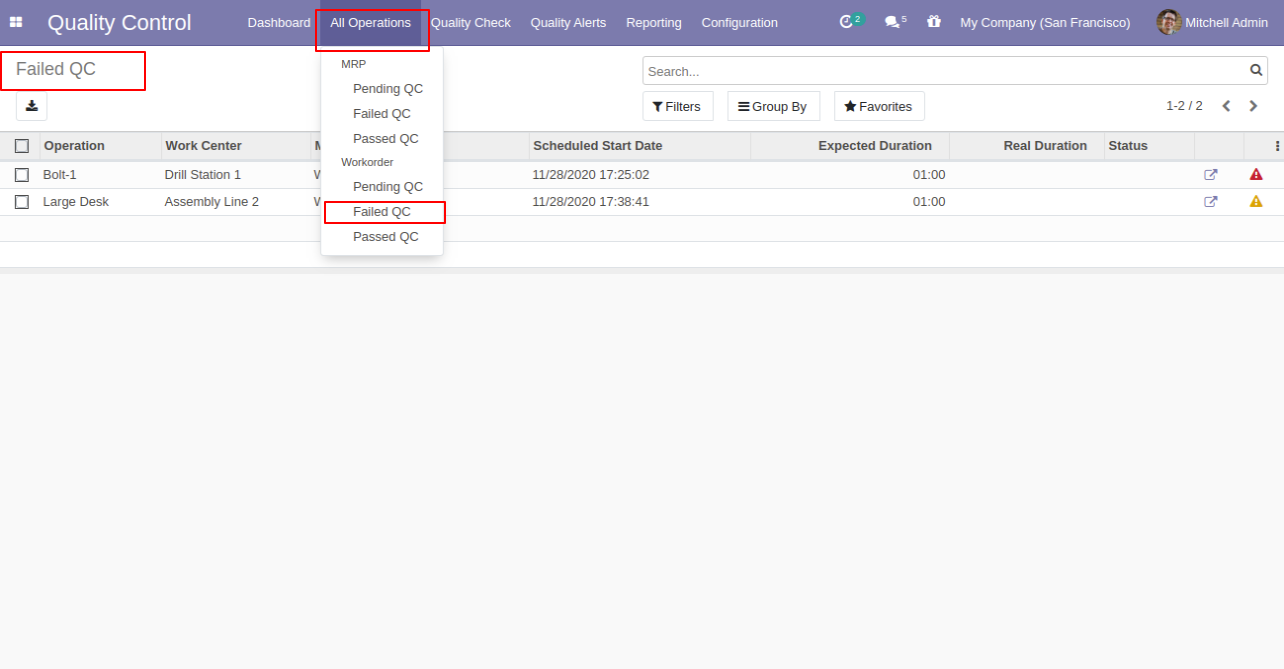

MRP Failed QC Menu and Tree View.

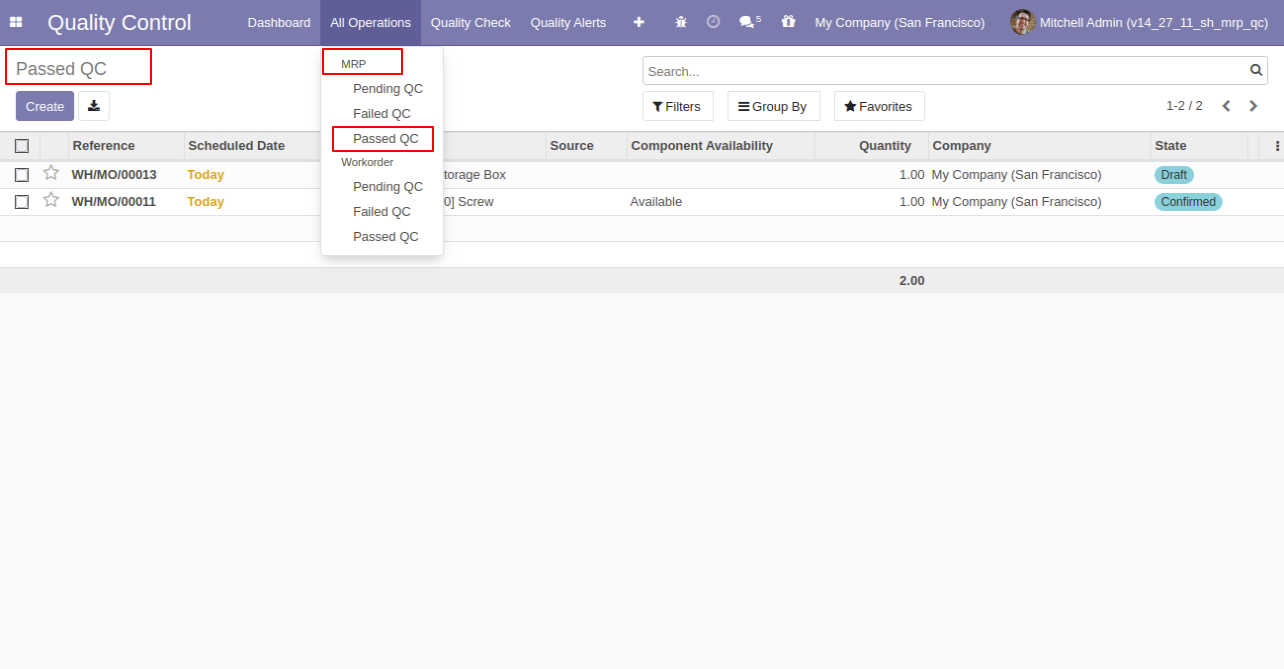

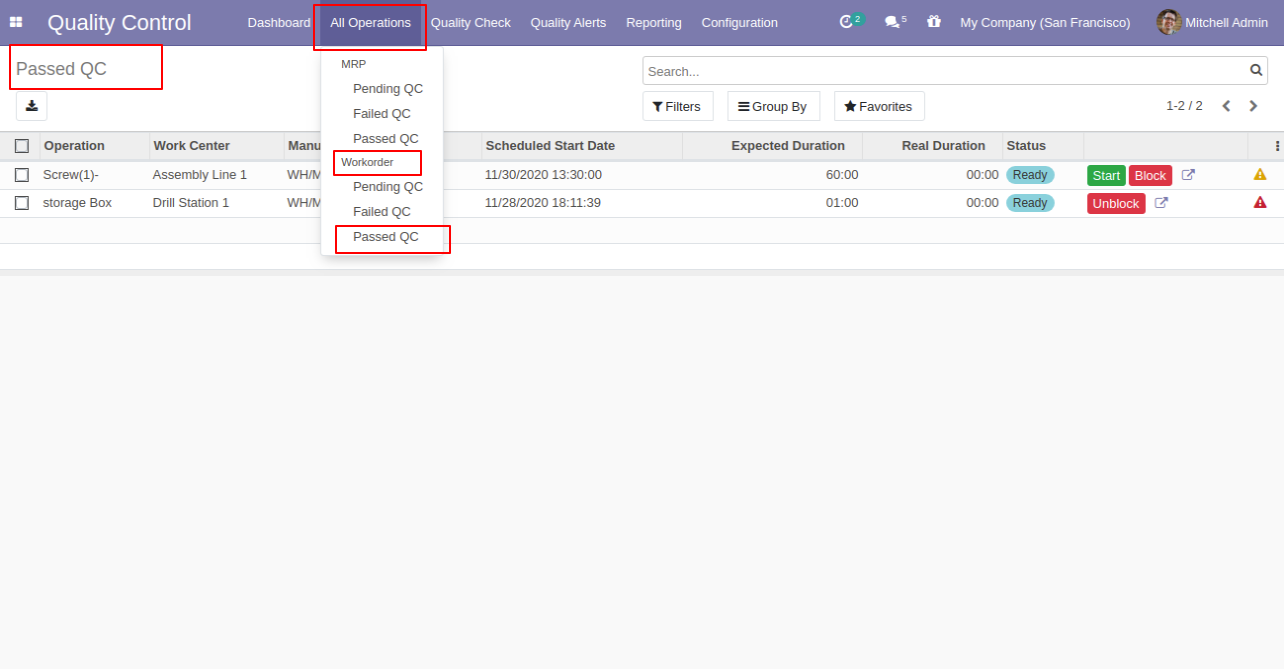

MRP Passed QC Menu and Tree View.

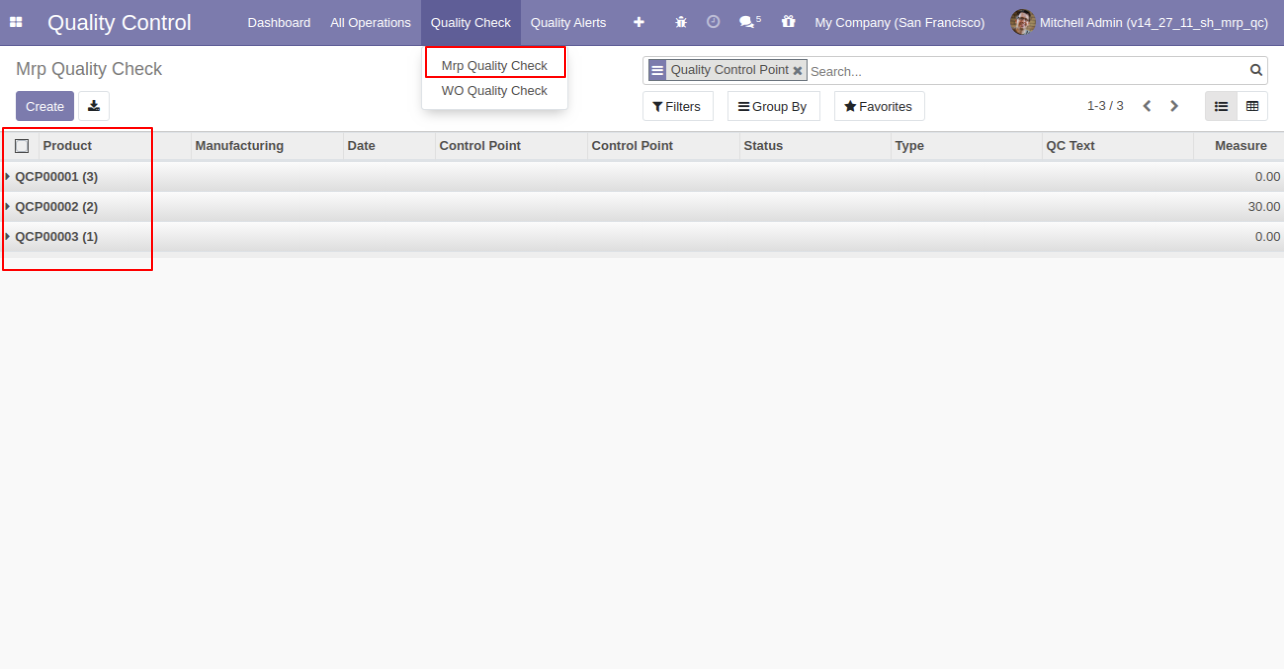

MRP Quality Check Menu and Tree View.

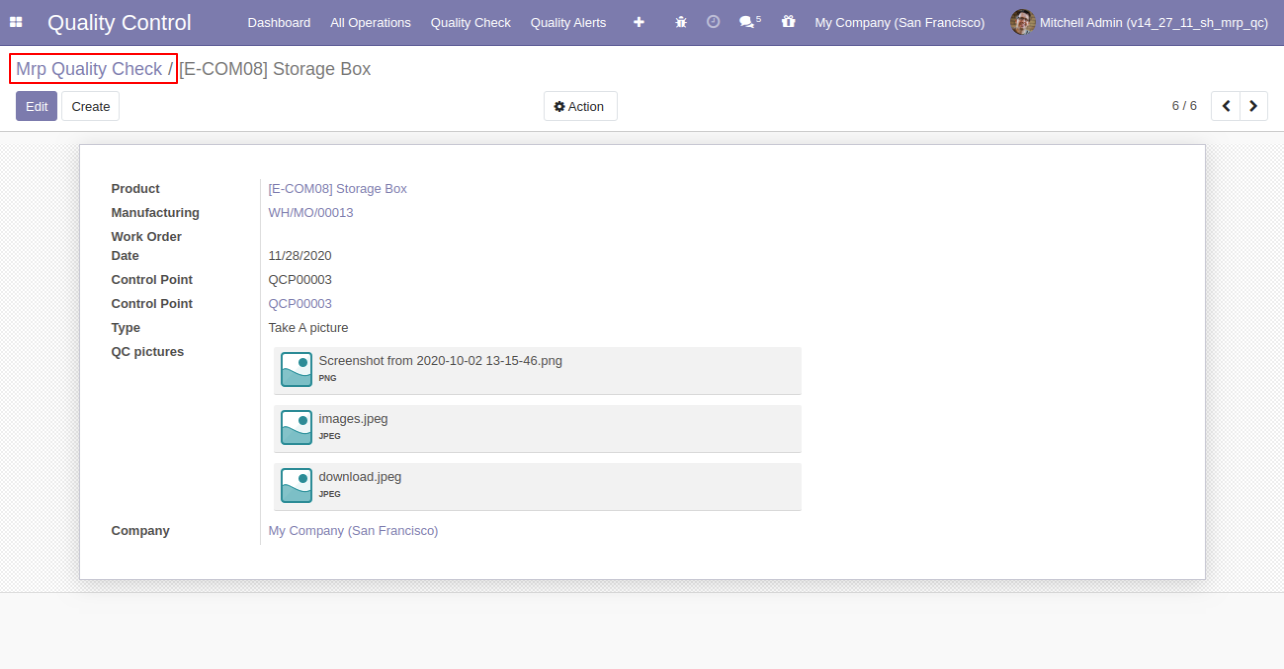

MRP Quality Check Form View.

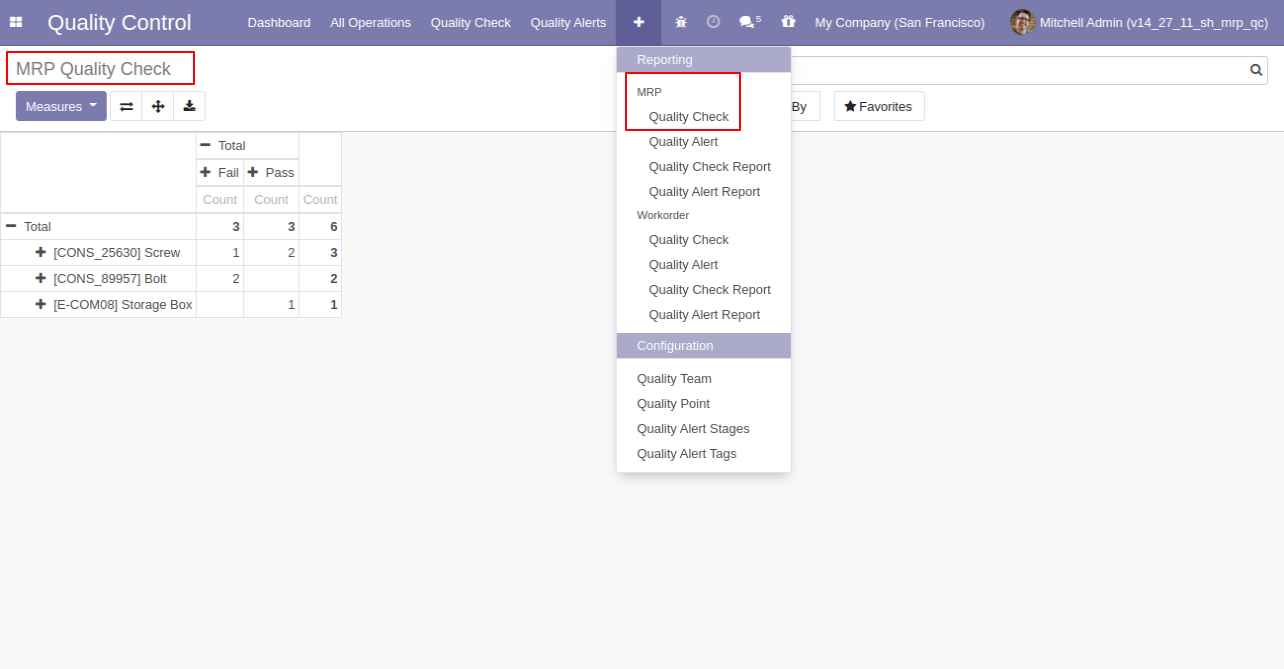

MRP Quality Check Analysis Report View.

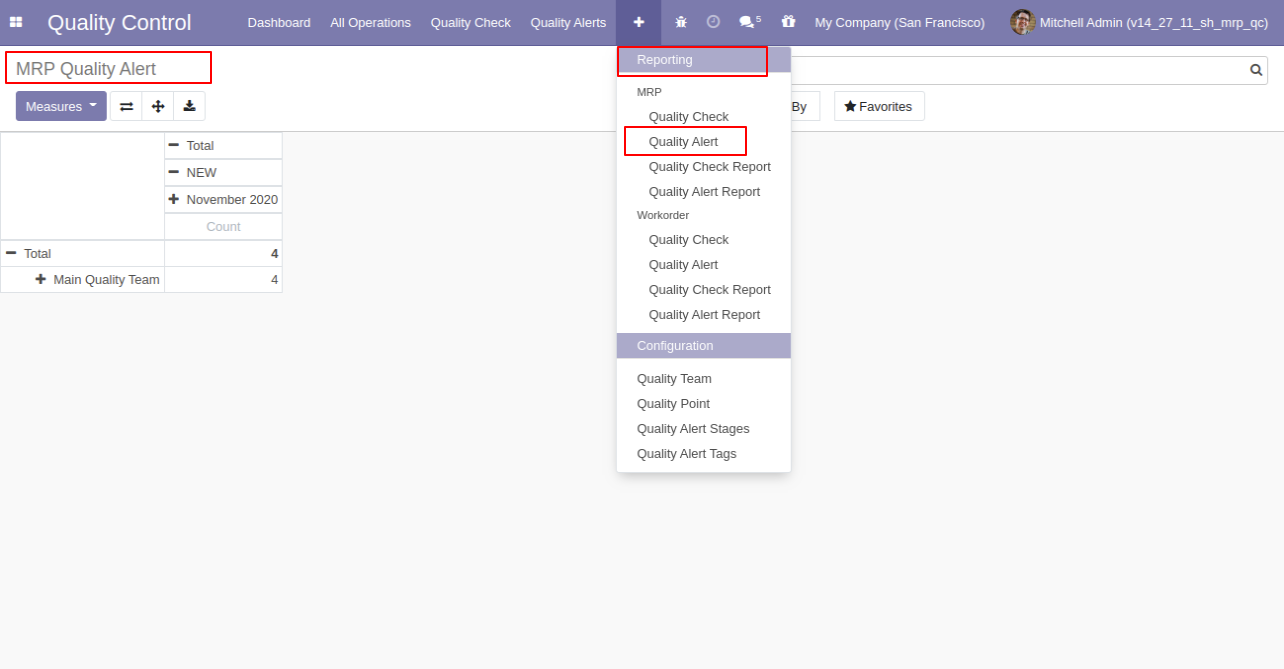

MRP Quality Alert Analysis Report View.

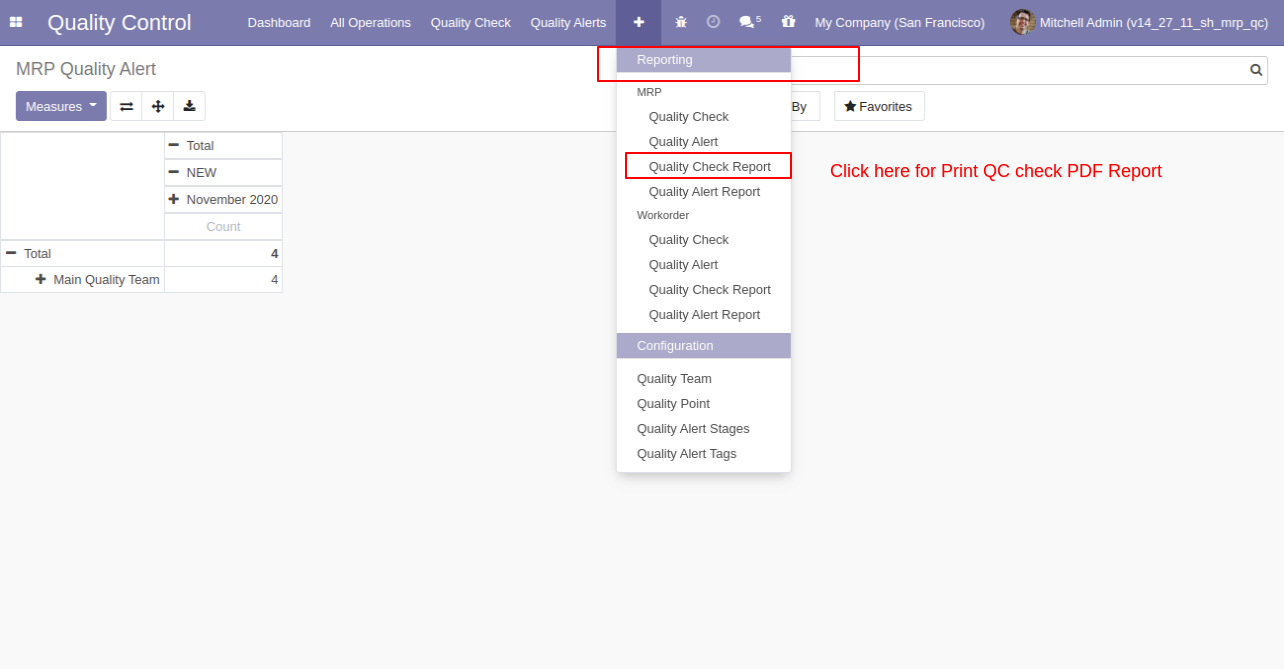

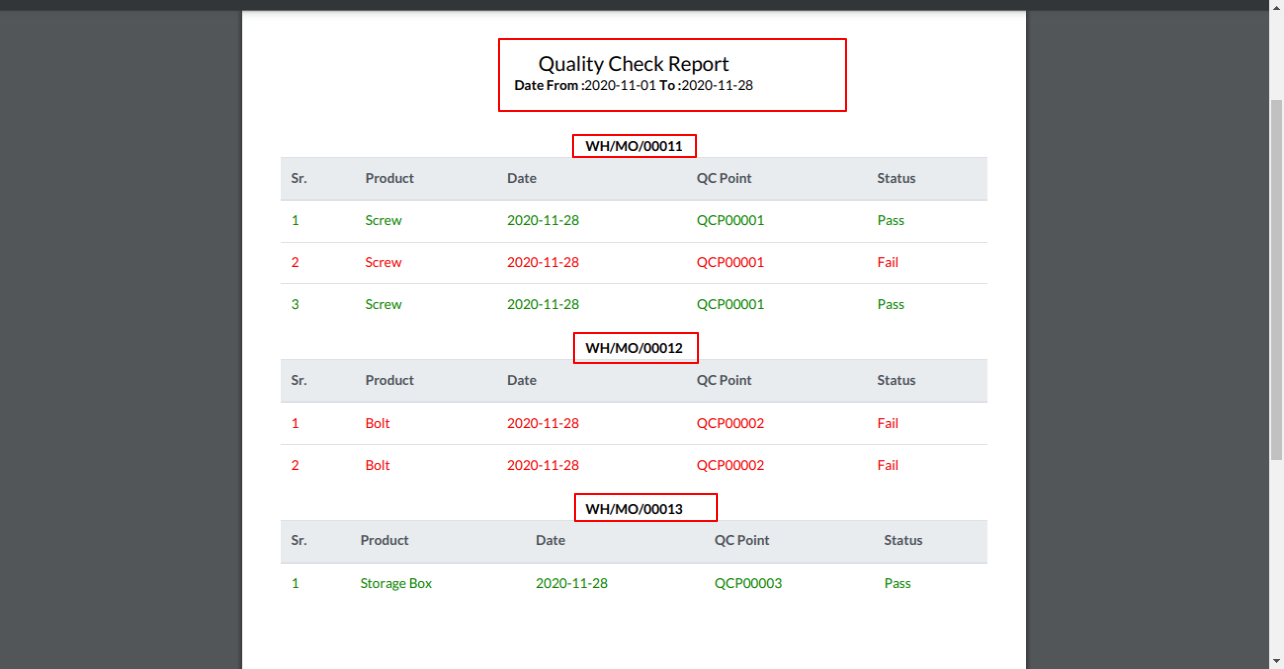

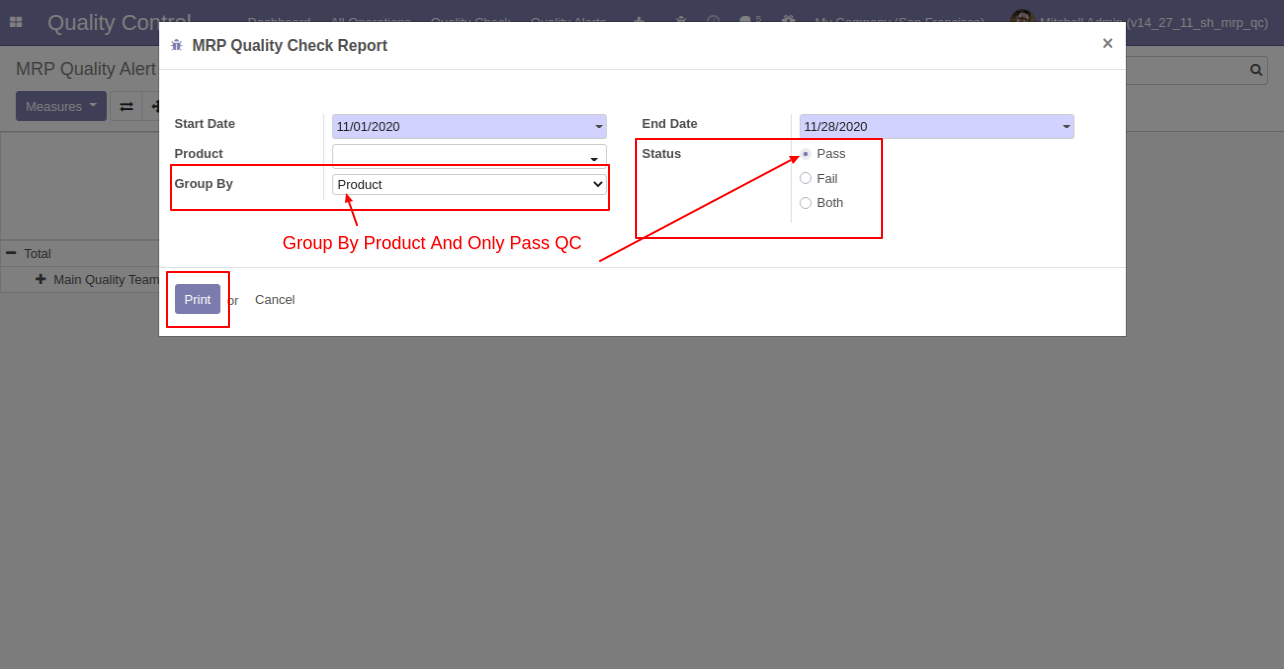

'Quality Check Report' for pdf report.

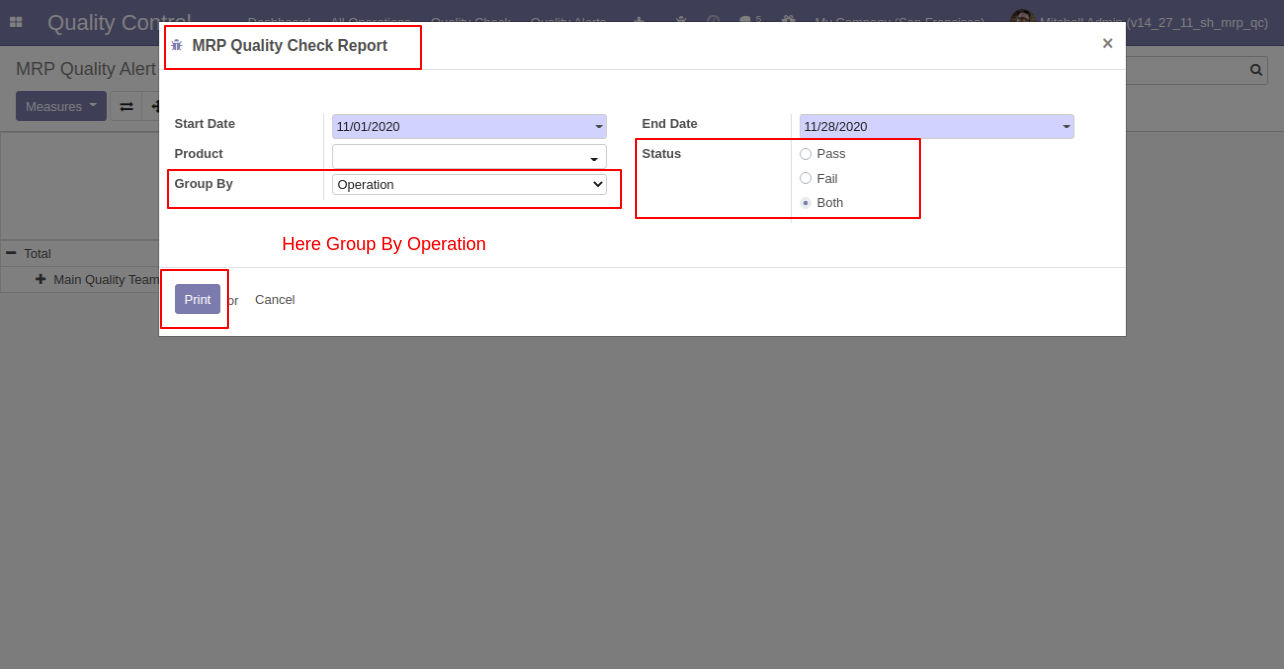

After click on 'Quality Check Report' this wizard will popup, select group by the operation and status both.

Quality Check PDF report with group by operation.

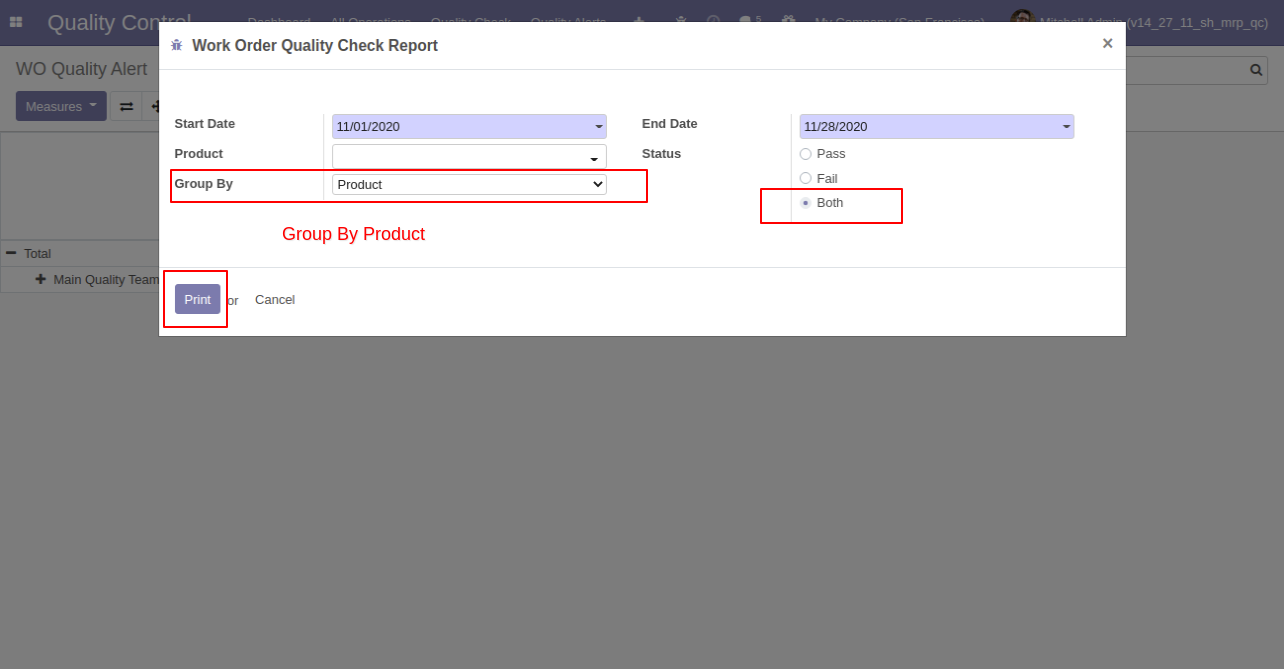

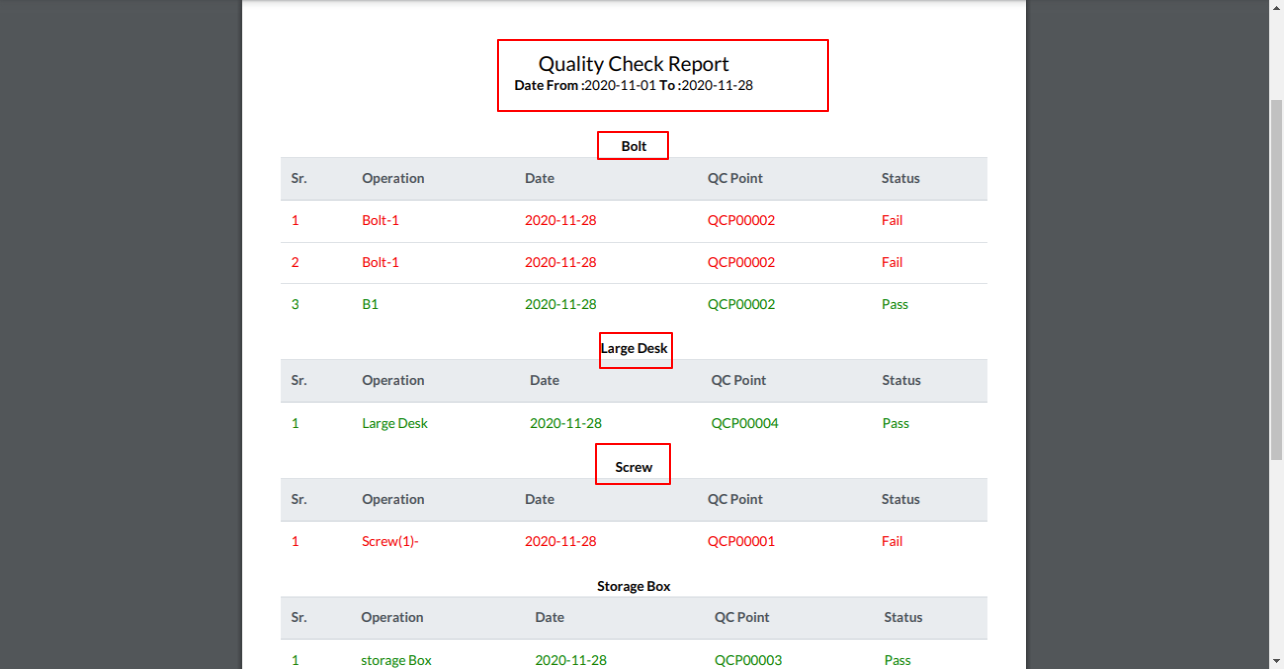

'Quality Check PDF Report' group by product and status pass.

Quality Check PDF Report group by product.

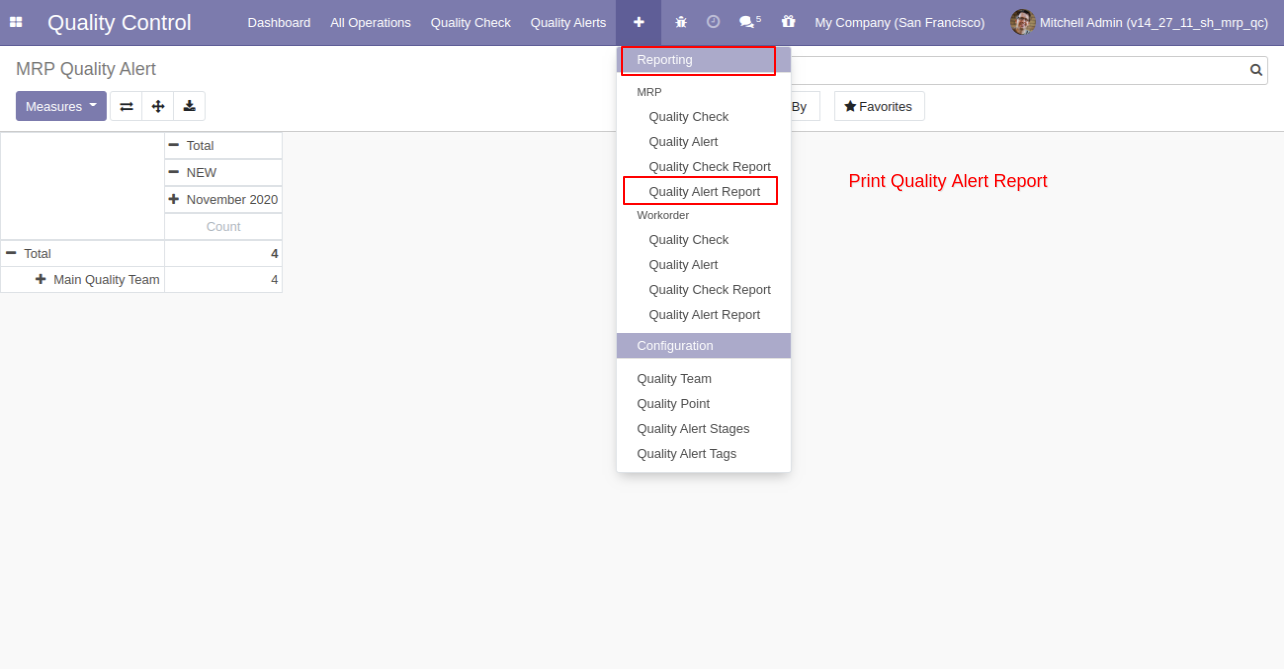

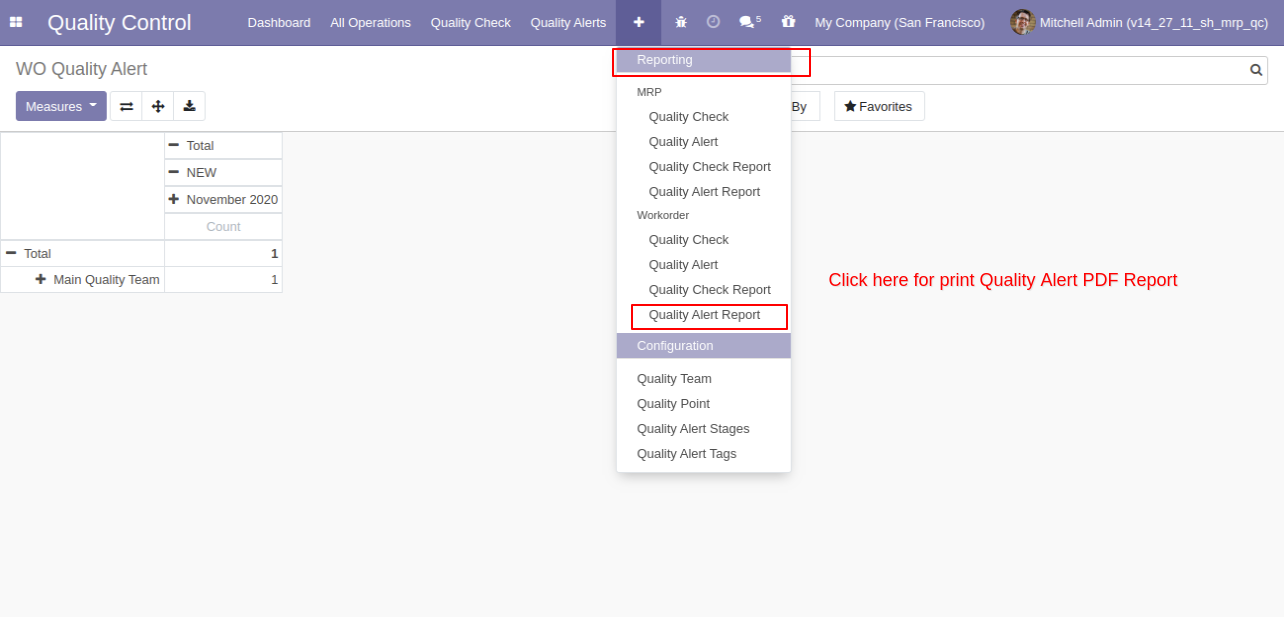

MRP Quality Alert PDF Report Action.

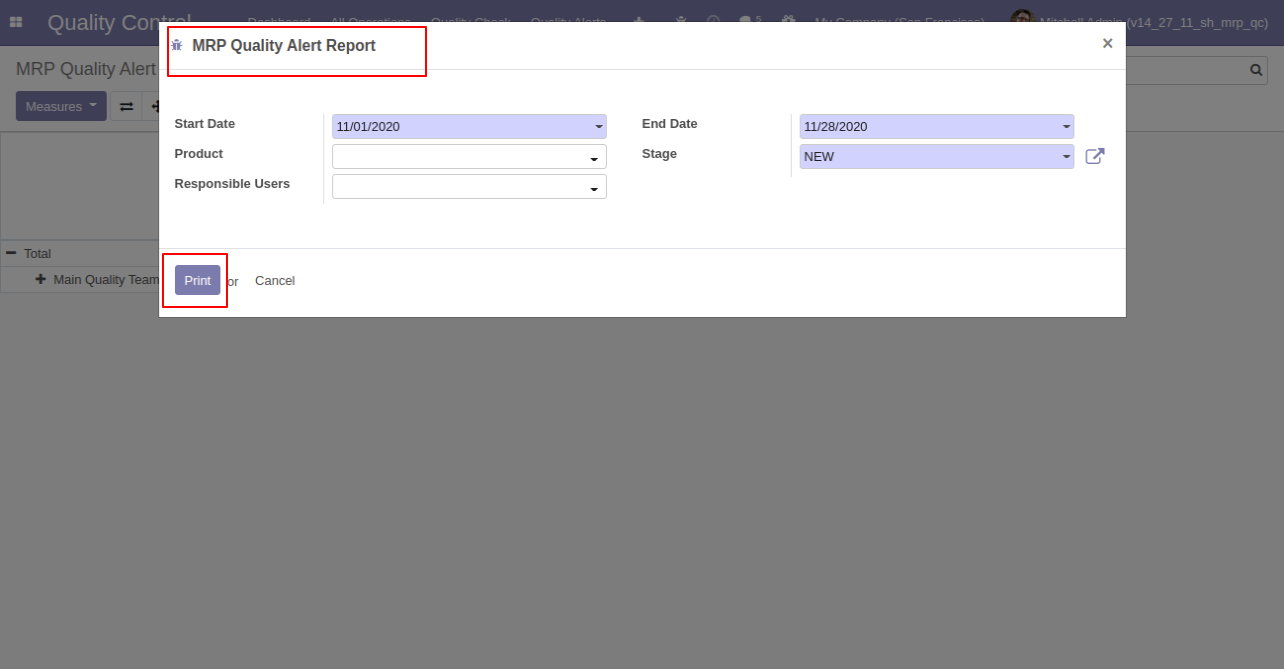

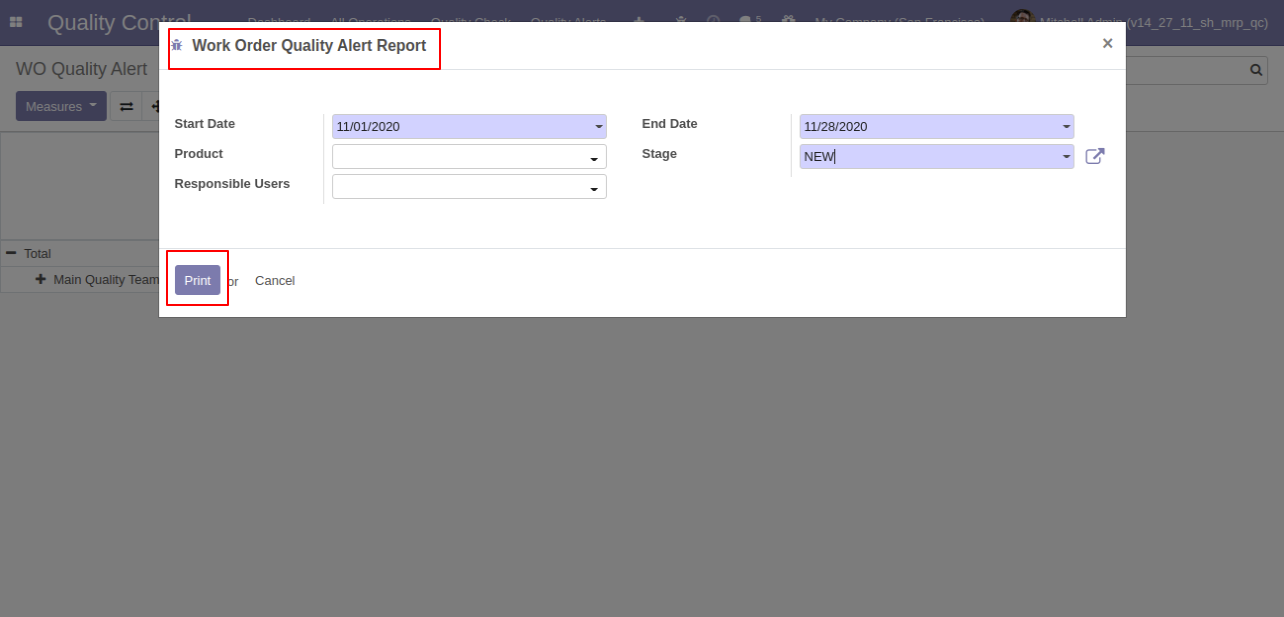

After click on 'Quality Alert Report' this wizard popup where you can filter and group by the report as per your requirements.

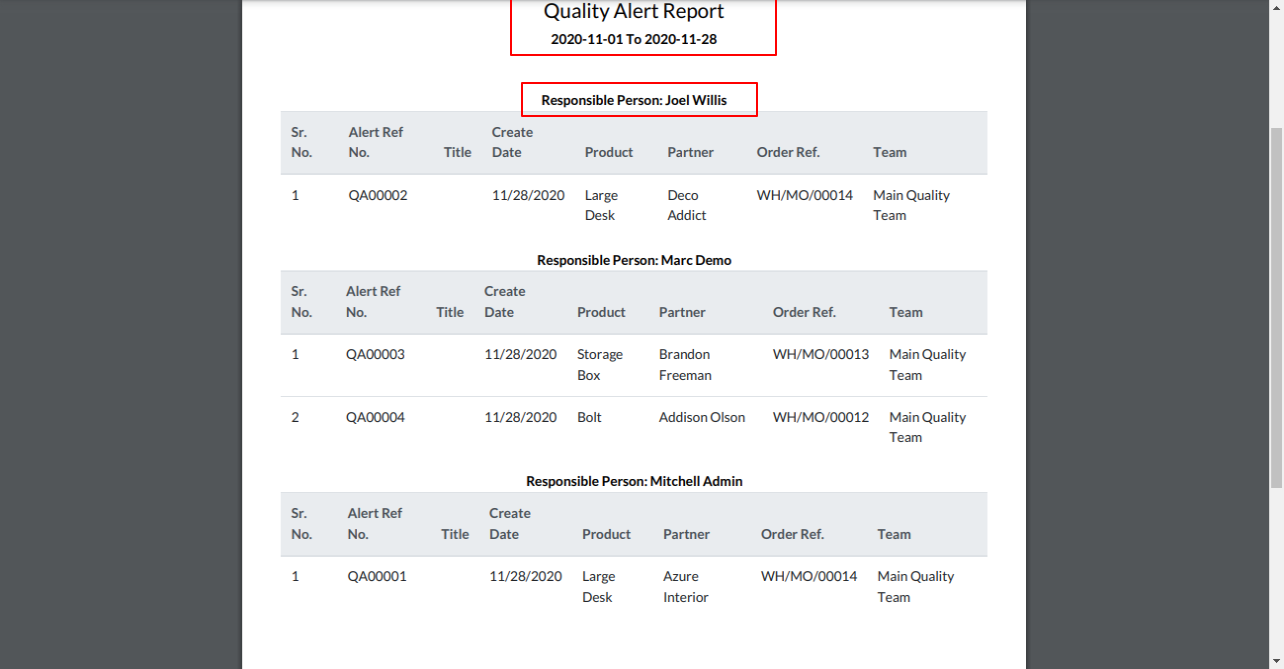

'Quality Alert PDF Report'.

In Quality Point you have to set product and piking type manufacturing.

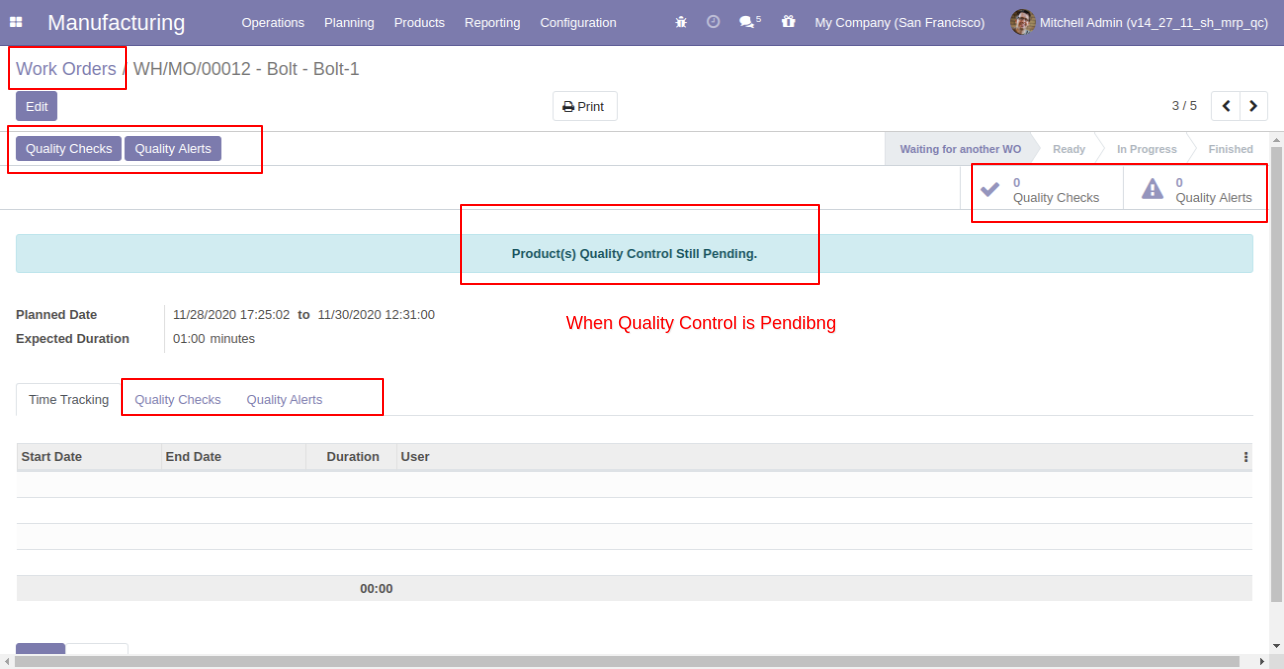

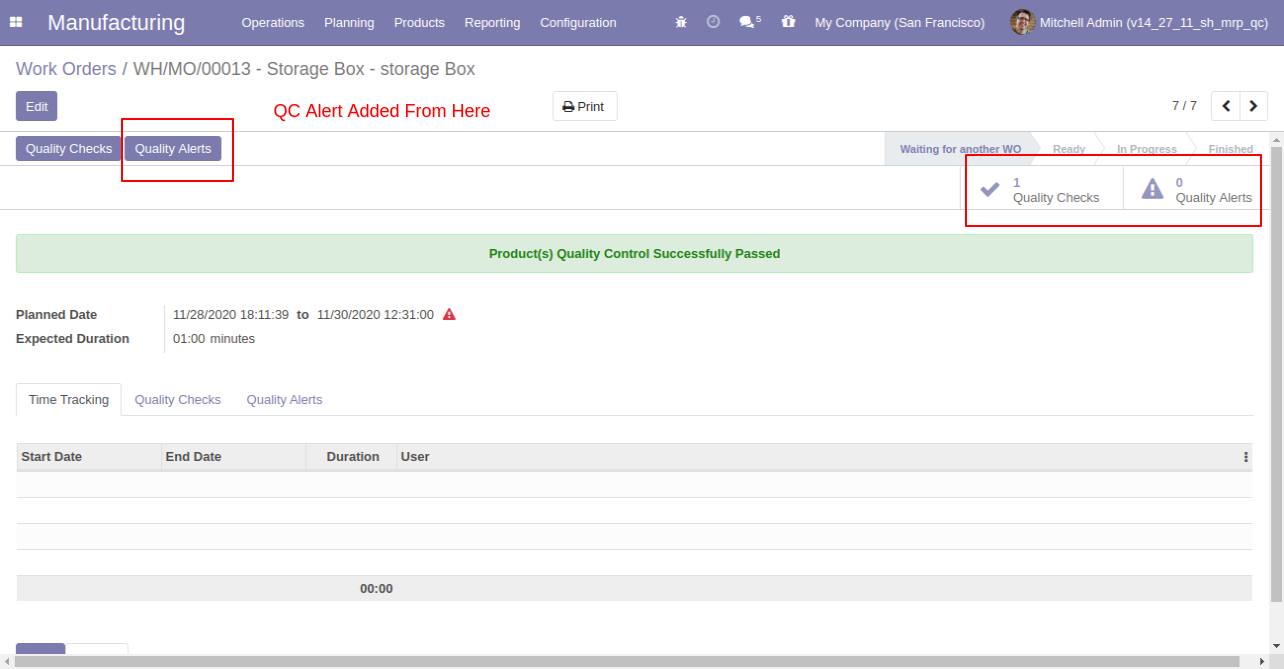

In work orders form view, there are two buttons "Quality Alerts" and "Quality Check", there are two smart buttons as you can see the quality alert and quality check, also see a global alert warning label on form top. There are two tabs for Quality Alert and Checks.

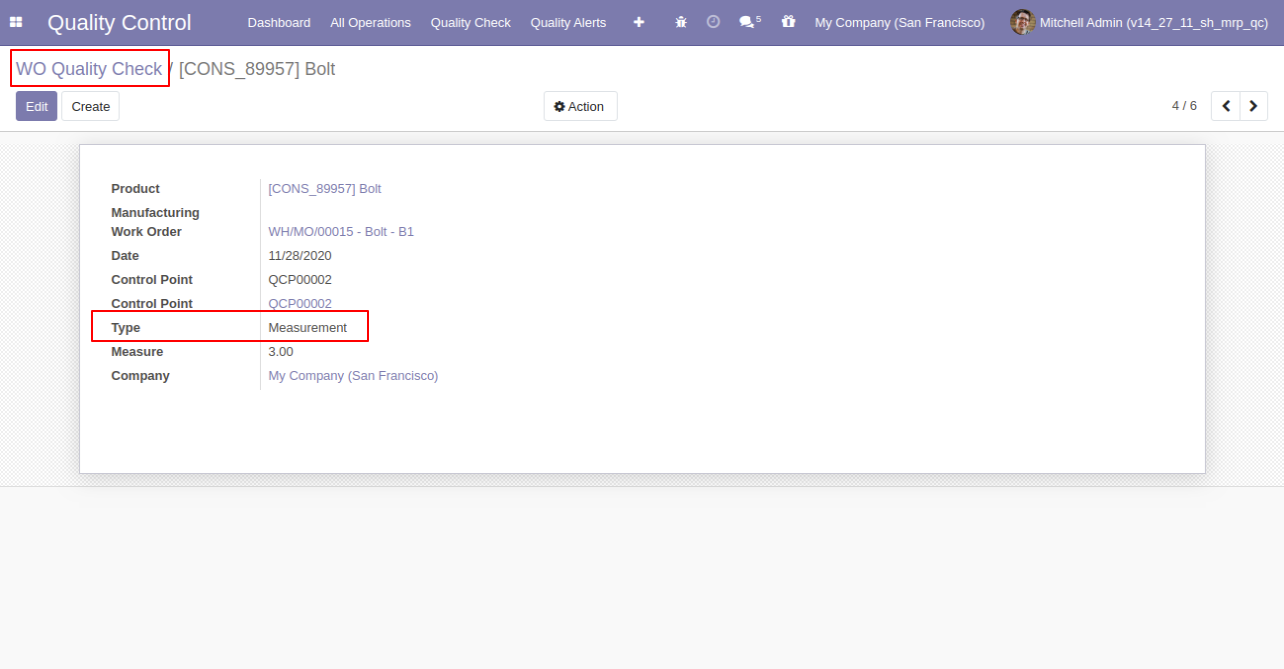

If quality check type 'Measurement' than a responsible person has to add the measurement of product quality.

If enter measurement does not match criteria then it will popup this message where you have to select, If enter measurement is correct then click 'Confirm Measure' else click 'Correct Measure' and it will redirect to you on the previous popup.

After clicking on the quality check, If check type 'Text Only' and click pass or fail.

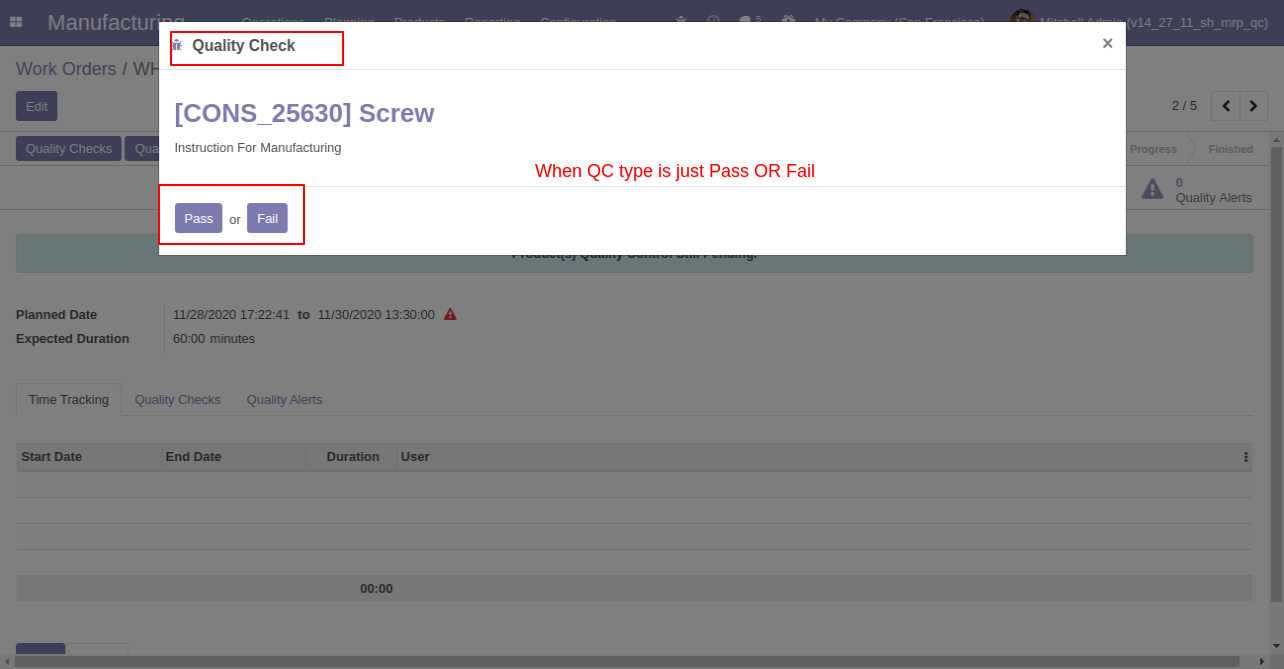

When Quality Check type 'Pass' or 'Fail'. A responsible person has to just click "Pass or Fail".

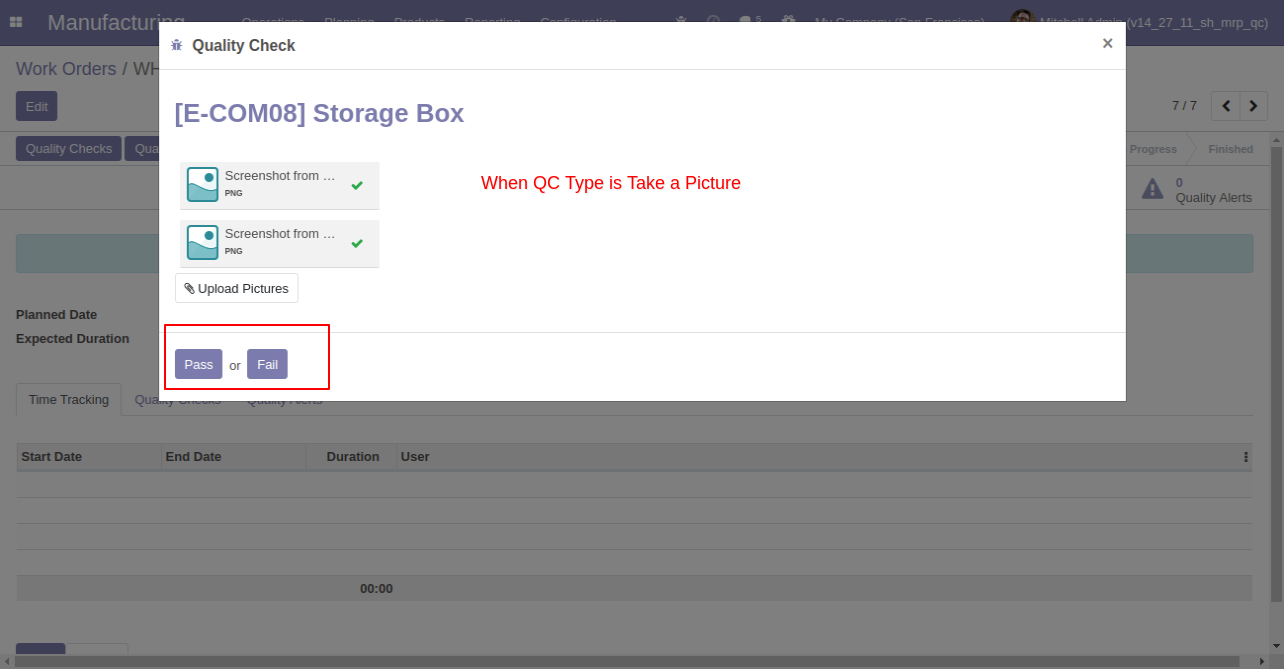

Quality Check Type "Take a Picture", Than responsible person has to add pictures of product quality.

Here users have buttons for 'Quality Alert' and one tab also.

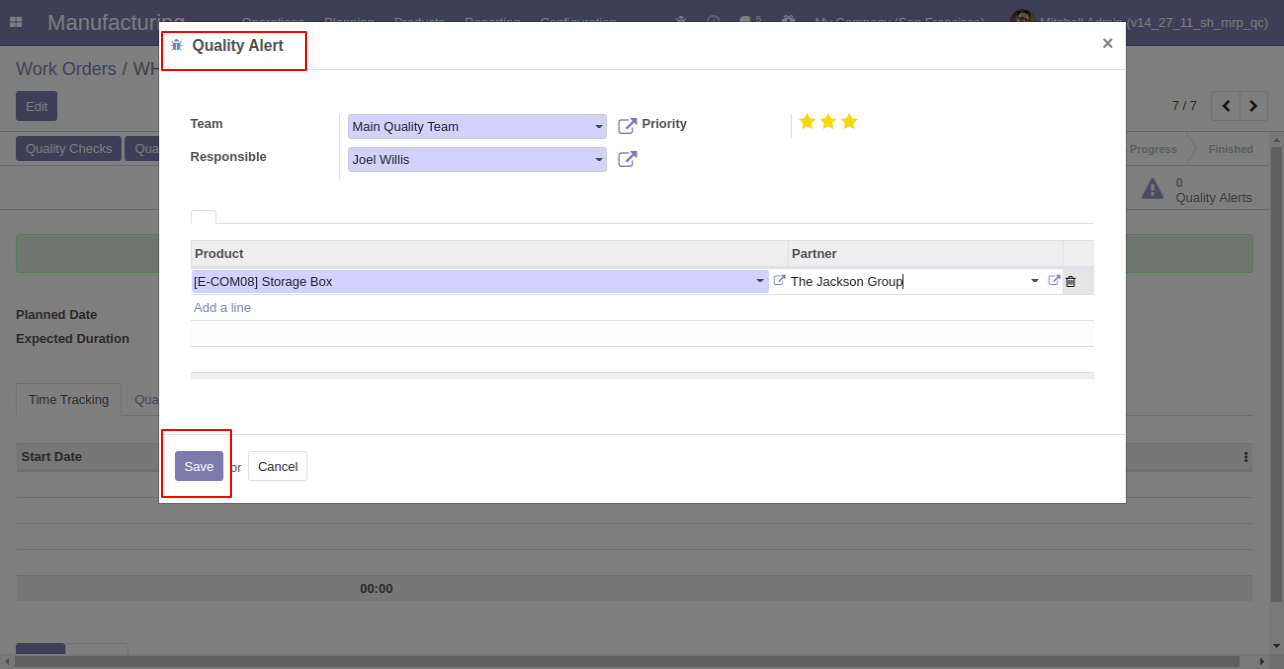

Quality Alert Wizard where you can create a quality alert for that product.

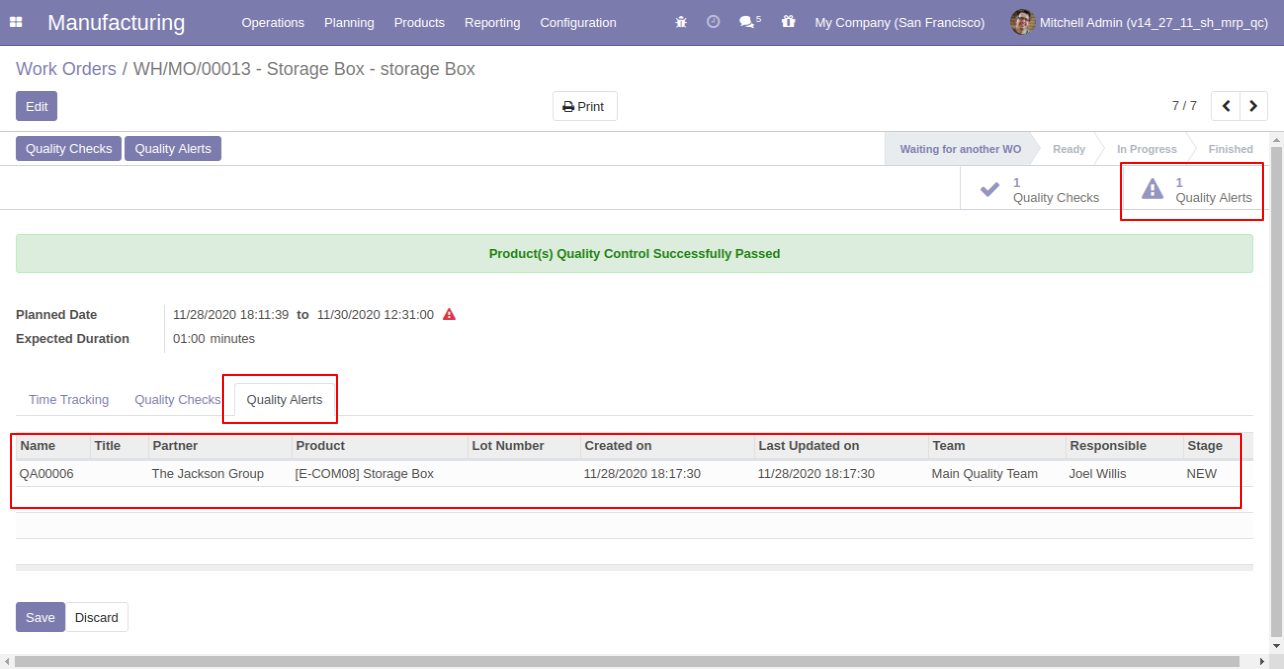

After save that you can see that product in the 'Quality Alert' tab and the smart button also.

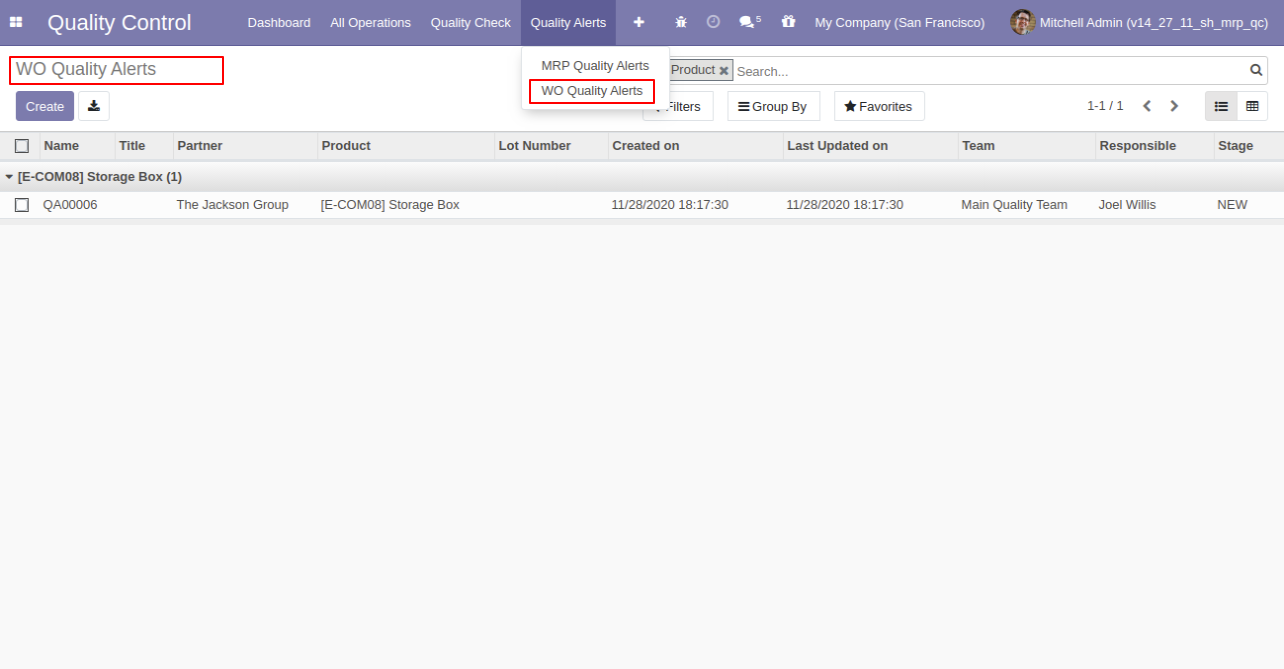

Work Order Quality Alerts Menu and Tree View.

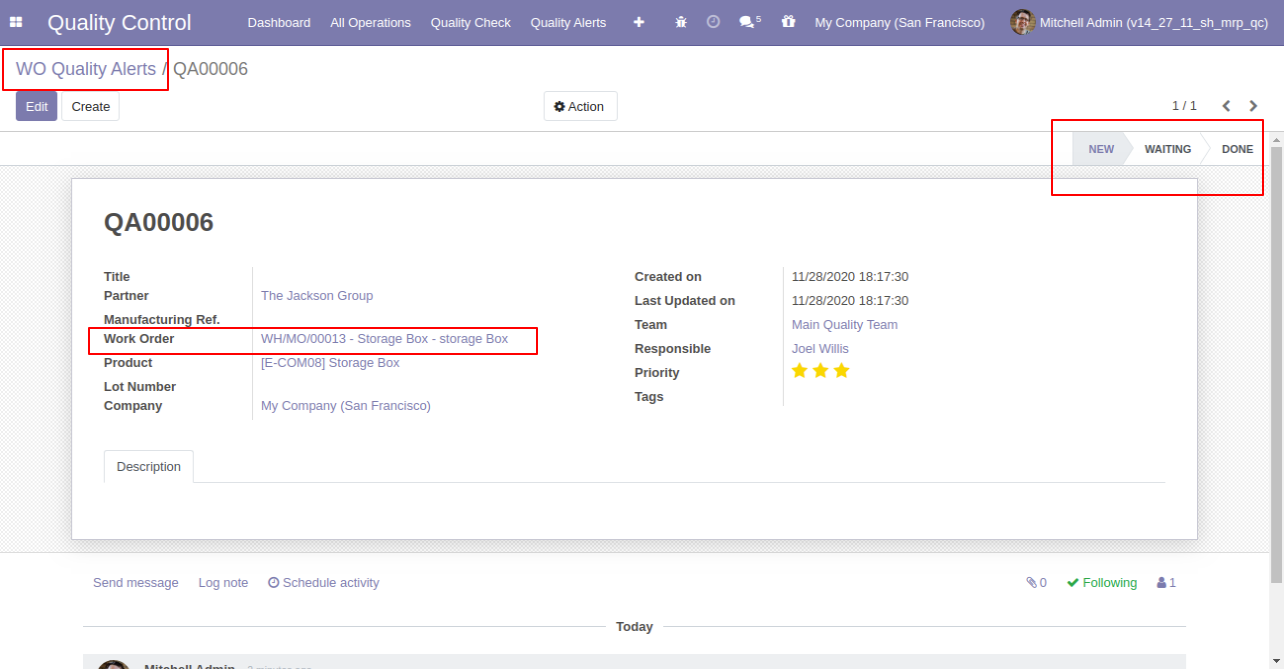

Work Order Quality Alerts Form View.

Work Order Pending QC Menu and Tree View.

Work Order Failed QC Menu and Tree View.

Work Order Passed QC Menu and Tree View.

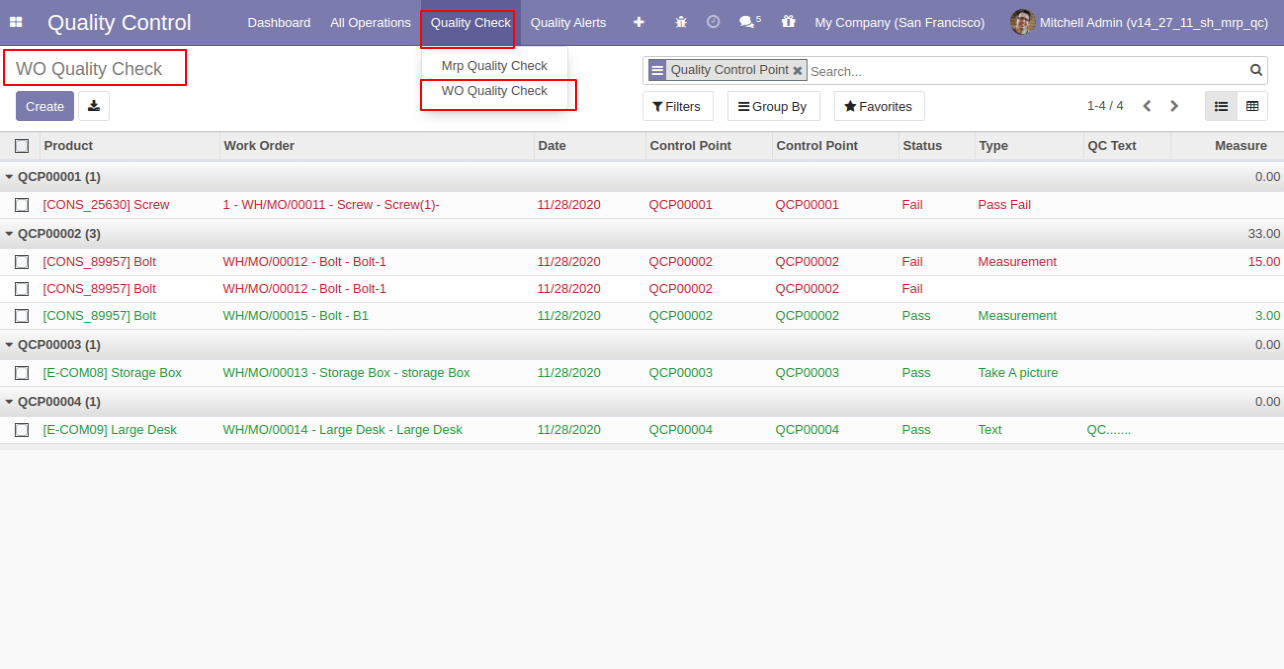

Work Order Quality Check Menu and Tree View.

Work Order Quality Check Form View. Where you can see the work order detail and type of QC.

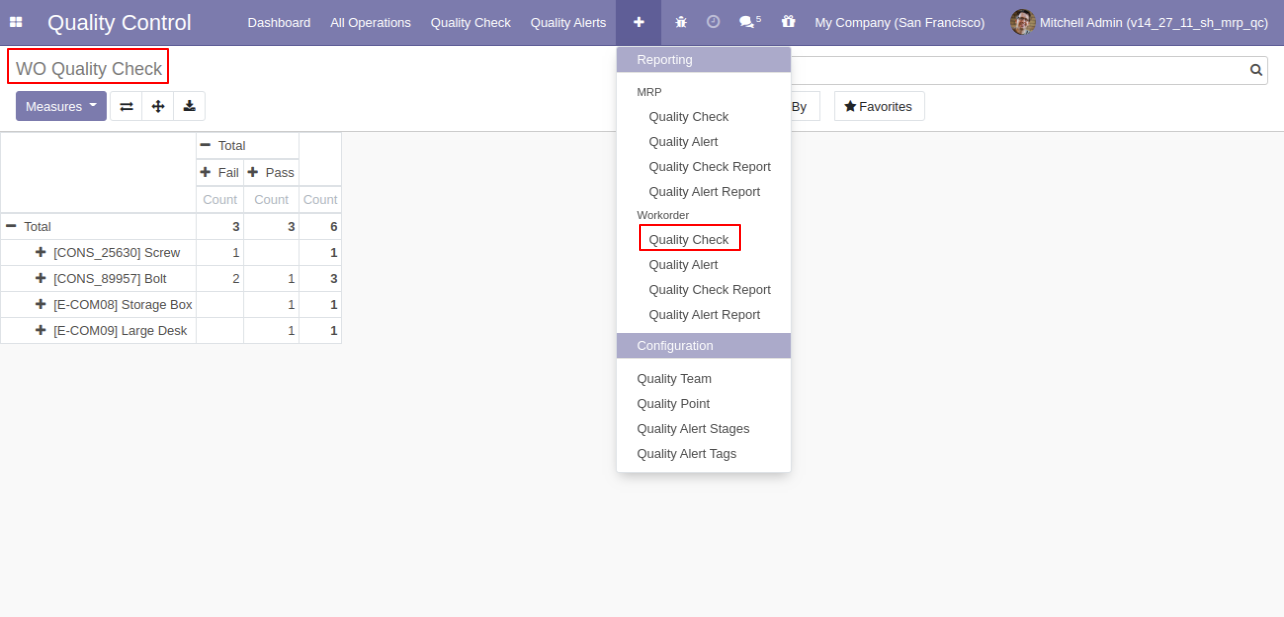

Work Order Quality Check Analysis Report Menu and View.

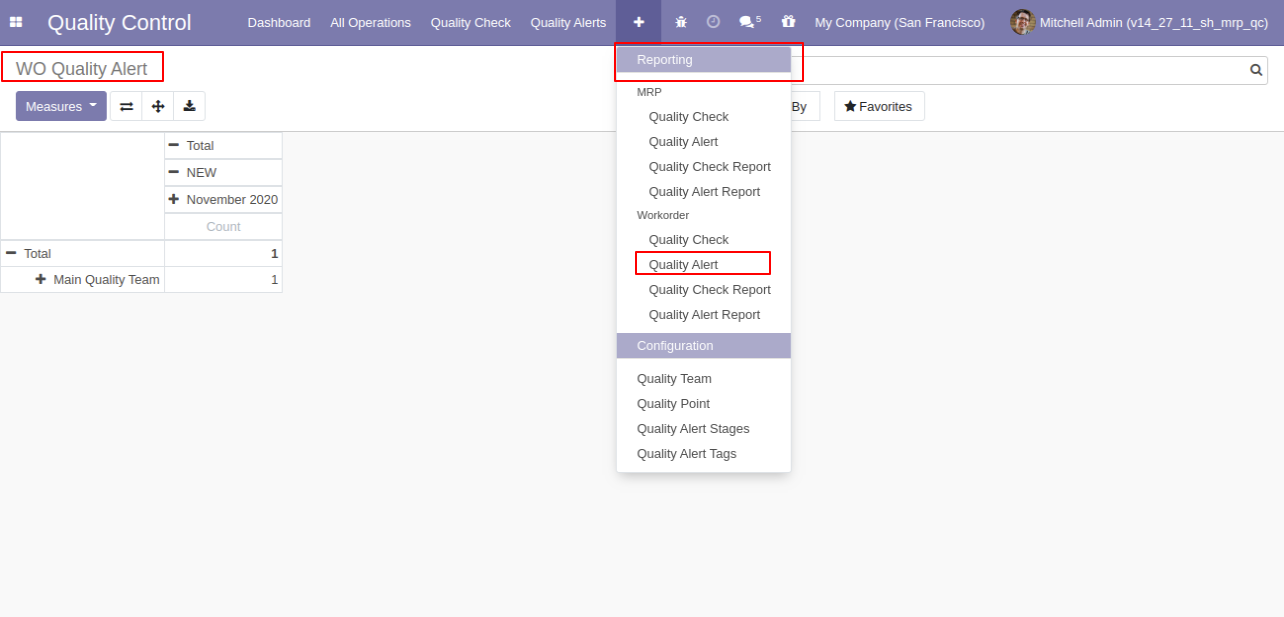

Work Order Quality Alerts Analysis Report Menu and View.

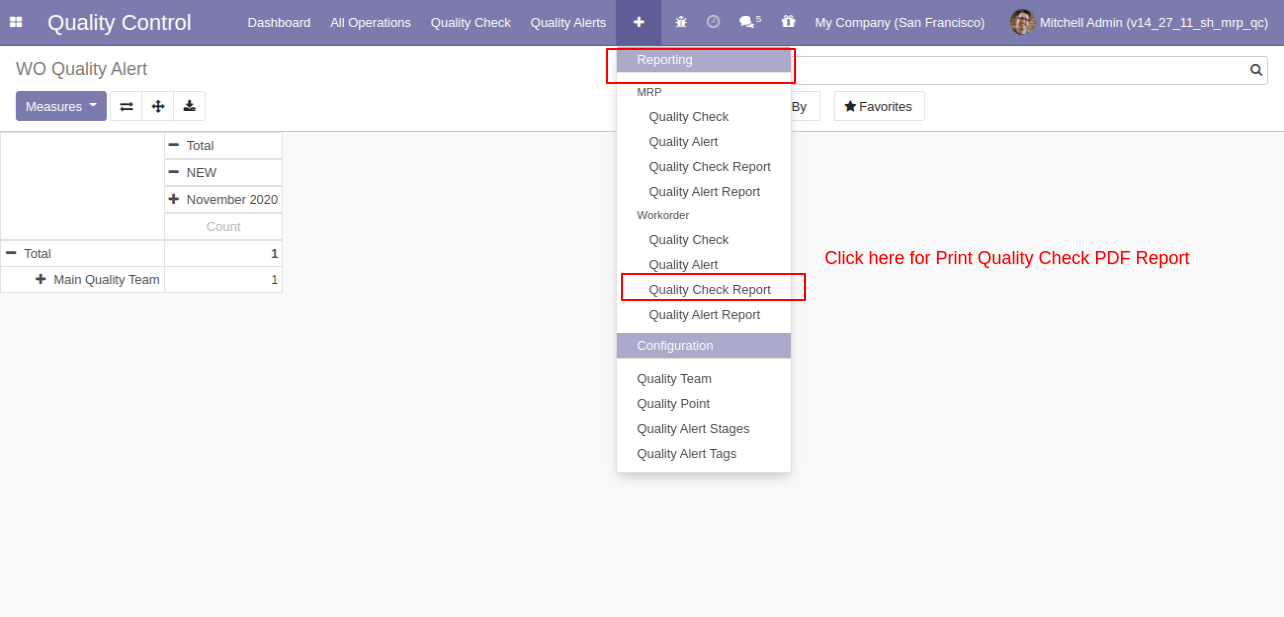

'Work Order Quality Check Report' action for print QC report in pdf format.

After clicking on that option this wizard will popup, where you can print reports with the group by, stages or start and end date filters.

This quality check pdf report is generated with the group by operation.

'Work Order Quality Alert Report' action for print QC report in pdf format.

After clicking on that option this wizard will popup, where you can print reports with the group by, stages or start and end date filters.

This quality alert pdf report is generated with the group by operation.

Version 13.0.1 | Released on : 2 December 2020

- Initial Release.

- This module works perfectly with Odoo Community only.

- Please Contact Us at sales@softhealer.com to request customization.

- You can set only a single quality point per product.

- Yes, we provide free upgrades as well as free support for 90 days.